Employment Application Apply

2025 Top Film Evaporator Technologies and Trends You Need to Know

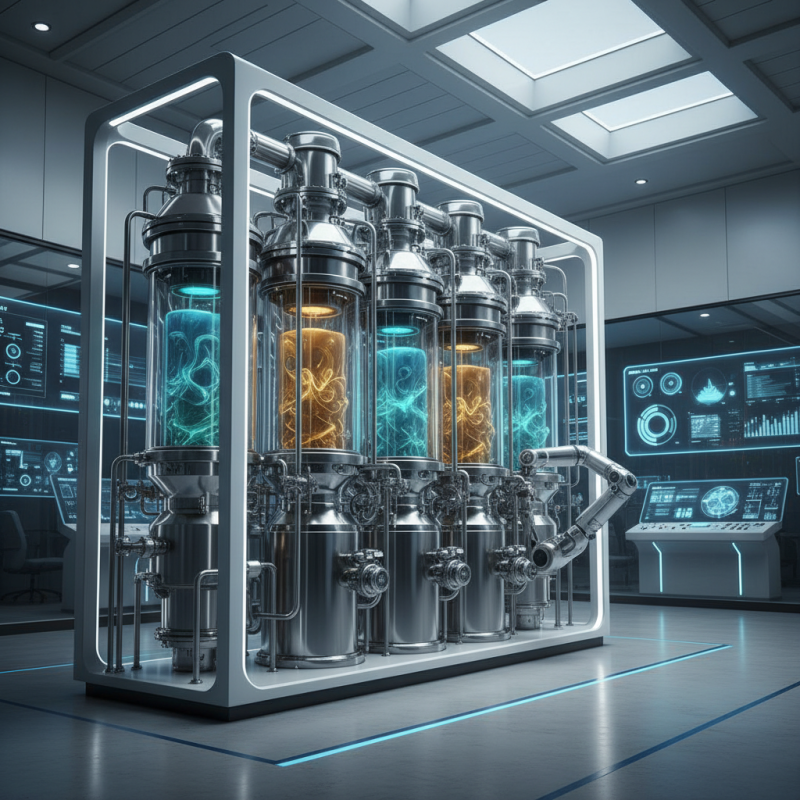

As we look ahead to 2025, the film evaporator technology landscape is set to undergo significant transformation. Film evaporators are critical components in various industrial processes, particularly in the food, pharmaceutical, and chemical sectors. Their ability to efficiently concentrate liquids while minimizing thermal degradation makes them invaluable in ensuring product quality. Understanding the latest advancements and trends in film evaporator technologies will be essential for professionals in these industries looking to optimize their operations and stay competitive.

The evolution of film evaporator systems has been driven by a combination of technological innovations and the increasing demand for energy-efficient solutions. Modern film evaporators are being designed with enhanced operational efficiencies, greater heat transfer capabilities, and reduced energy consumption. With growing environmental concerns, the integration of sustainable practices into the design and function of these systems is becoming a pivotal trend. This article will explore the key technologies shaping the future of film evaporators, along with the trends that professionals need to embrace to adapt to the changing landscape of industrial processing.

Emerging Technologies in Film Evaporators for 2025

As we move towards 2025, the landscape of film evaporator technologies is evolving rapidly, driven by the need for increased efficiency and sustainability in industrial processes. Emerging technologies in this field are focusing on enhancing thermal performance and reducing energy consumption through innovative design and materials. Advanced heat exchange systems, such as multi-effect evaporators and falling film configurations, are gaining traction, allowing for better temperature control and reduced operational costs. These developments not only optimize the evaporation process but also significantly lower the carbon footprint associated with manufacturing.

Moreover, automation and smart technologies are becoming integral to film evaporators. The integration of IoT devices enables real-time monitoring and predictive maintenance, enhancing the reliability and efficiency of these systems. Machine learning algorithms analyze operational data to optimize process parameters and improve yield, making the systems more adaptive to varying raw material inputs. This trend towards smarter technology reflects a broader shift in industrial practices, where data-driven decisions are paramount for maintaining competitiveness and sustainability in an increasingly environmentally-conscious market.

2025 Top Film Evaporator Technologies and Trends

Advancements in Efficiency and Performance Metrics

As the film evaporator technology evolves, the focus on efficiency and performance metrics has intensified. Recent studies from the American Society of Mechanical Engineers (ASME) indicate that advancements in thermal efficiency can lead to a 20% reduction in energy consumption, significantly impacting operational costs. Not only does this translate to lower energy bills, but it also aligns with global sustainability goals by reducing greenhouse gas emissions. The integration of automatic control systems has been pivotal, enhancing precision in temperature and pressure management, which are crucial for optimal evaporation processes.

Moreover, innovation in materials science has led to the development of advanced coatings that improve heat transfer and reduce fouling, thereby increasing the overall performance of these systems. According to a report by the International Institute of Refrigeration (IIR), new surface technologies can improve heat transfer coefficients by up to 30%, making these systems more effective and efficient. As industries continue to prioritize sustainability and cost-effectiveness, the adoption of these cutting-edge film evaporator technologies will play a vital role in reshaping operational practices across various sectors.

Sustainable Practices and Eco-Friendly Innovations

As the film processing industry continues to evolve, sustainable practices and eco-friendly innovations are becoming paramount. Reports indicate that the global evaporator market is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2028, driven largely by an increasing emphasis on reducing environmental impact. One of the most significant trends in this space is the adoption of advanced technologies that minimize energy consumption and waste generation. Innovations like regenerative thermal oxidizers and membrane filtration systems offer efficient alternatives to traditional methods, providing both environmental benefits and cost savings.

Moreover, sustainability in evaporator technologies is gaining traction through the use of renewable energy sources. According to a recent study, facilities that integrate solar or wind energy into their operations can reduce carbon emissions by up to 30%. Additionally, companies are increasingly utilizing water recycling systems in evaporator designs, with reports showing that such systems can enhance water recovery rates by 50%, significantly conserving this vital resource. As the industry embraces these eco-friendly innovations, the focus remains on developing systems that are not only efficient but also align with broader sustainability goals, paving the way for a greener future in film processing.

Key Players and Market Trends Shaping the Industry

The film evaporator technology landscape is rapidly evolving, driven by advancements in materials science and engineering. As industries demand more efficient processes, key players in the market are focusing on innovative designs that enhance thermal efficiency and reduce energy consumption. Recent trends indicate a shift towards automation and smart controls in evaporator systems, allowing for real-time monitoring and adjustments that optimize performance. This trend not only increases operational efficiency but also minimizes operational costs, making the technology more accessible to a wider range of applications.

In addition to technological advancements, sustainability has become a pivotal influence on market trends. Companies are increasingly seeking ways to reduce their environmental footprint, prompting the integration of eco-friendly practices and materials in film evaporator designs. As regulations regarding emissions and waste management tighten, the adoption of greener technologies will likely become a standard requirement in the industry.

Tips: When evaluating film evaporator options, consider the long-term operational costs and sustainability features. Investing in systems that offer enhanced efficiency not only contributes to immediate savings but also aligns with global sustainability goals. Moreover, staying informed about emerging technologies can position businesses to capitalize on the latest advancements, ensuring they remain competitive in an evolving market.

Future Predictions and Challenges in Film Evaporation Technology

The film evaporation technology landscape is rapidly evolving, with advancements promising greater efficiency and sustainability. As industries strive to adopt greener practices, the focus is increasingly on innovative techniques that minimize waste and energy consumption. Future predictions indicate that developments in nanotechnology and materials science will play a crucial role in enhancing the performance of film evaporators. These improvements not only aim to optimize thermodynamic efficiency but also address environmental challenges, making the technology more appealing for various applications.

Tip: When evaluating film evaporator systems, consider their energy efficiency ratings and the potential for integration with renewable energy sources. This can help you align your operations with sustainability goals while also reducing operational costs.

However, challenges persist in the implementation and scalability of these next-generation film evaporation technologies. High initial investment costs and the need for specialized knowledge can deter many businesses from transitioning to newer systems. Additionally, regulatory hurdles may slow the adoption of innovative solutions. It is essential for stakeholders to keep abreast of industry regulations and engage in continuous learning to navigate these challenges effectively.

Tip: Join industry forums and attend workshops to stay updated on the latest trends and technological advancements in film evaporation. Networking with experts can provide invaluable insights and support for overcoming current barriers.

2025 Top Film Evaporator Technologies and Trends You Need to Know

| Technology | Key Features | Trends | Challenges |

|---|---|---|---|

| Thin Film Deposition | High precision and uniformity | Growing demand in electronic applications | Material costs and waste management |

| Rotary Evaporator Technology | Efficient solvent recovery | Increased efficiency in laboratory processes | Maintenance complexity and scalability |

| Falling Film Evaporators | Enhanced heat transfer rates | Adoption in food and pharmaceutical sectors | Scaling up production capacity |

| Spray Evaporators | Ideal for heat-sensitive materials | Rising use in nutraceuticals | Optimization of drying times and costs |

| Short-Path Distillation | Low operational temperatures | Demand in essential oils and fragrances | High initial investment costs |