Employment Application Apply

Top 10 Benefits of Using Luwa Evaporator for Your Industrial Processes

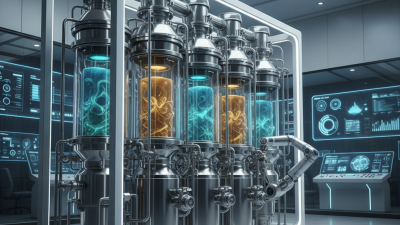

In the fast-evolving world of industrial processes, the efficiency and effectiveness of equipment play a critical role in achieving operational excellence. Among the leading solutions available in the market, the Luwa evaporator stands out for its innovative design and remarkable benefits. According to Dr. James Hawthorne, a renowned expert in the field of industrial evaporation technology, "The Luwa evaporator is a game changer, offering unmatched thermal efficiency and sustainability advantages." This statement underscores the growing recognition of the Luwa evaporator as a vital component in modern industrial applications.

The top ten benefits of using a Luwa evaporator extend beyond mere evaporation rates; they encompass cost savings, enhanced product quality, and environmental sustainability. Each of these advantages contributes to a more streamlined manufacturing process, allowing businesses to meet their operational goals while minimizing their ecological footprint. As industries increasingly focus on optimizing their processes in an environmentally responsible manner, the Luwa evaporator provides a forward-thinking solution that aligns with both productivity and sustainability objectives. By incorporating this advanced technology into their systems, companies can pave the way for a more efficient and profitable future.

Key Features of Luwa Evaporators in Industrial Applications

Luwa evaporators are engineered to enhance the efficiency and effectiveness of industrial processes, offering several key features that stand out in various applications. One of the notable characteristics is their high thermal efficiency, which allows for rapid evaporation rates while minimizing energy consumption. This translates to cost savings and a lower environmental impact, making these systems a preferred choice for industries aiming for sustainability.

Another crucial feature is their versatility in handling different materials. Luwa evaporators are designed to process various concentrations and types of feedstocks, making them adaptable to many industrial demands. This flexibility enables manufacturers to optimize production processes, tailor configurations to specific product needs, and maintain quality control without compromising efficiency.

Tips: When selecting an evaporator system, it's essential to consider the specific thermal properties of the materials you’ll be processing. Conducting a thorough analysis of your evaporation requirements can help choose the right system for your operations. Additionally, regular maintenance and monitoring can enhance performance, prolong the life of the equipment, and improve process outcomes.

Enhanced Efficiency and Performance of Luwa Evaporators

The efficiency and performance of evaporators play a crucial role in various industrial processes, where they facilitate the effective removal of moisture from products. Utilizing advanced evaporator technology can significantly enhance operational workflows, leading to improved productivity and reduced energy consumption. The incorporation of state-of-the-art design and engineering allows these evaporators to achieve optimal heat transfer rates, ensuring that products reach desired moisture levels while maintaining quality.

Moreover, the advanced features of modern evaporators allow for greater control over processing conditions. This adaptability means that industries can optimize their production parameters, resulting in better yield and reduced waste. Enhanced automation systems provide real-time monitoring and analytics, allowing operators to swiftly respond to any fluctuations in the process, which contributes to maintaining consistent output quality. By leveraging such capabilities, businesses can streamline their operations, leading to long-term sustainability and cost savings.

Cost Savings and Economic Benefits of Using Luwa Evaporators

The use of evaporators in industrial processes can lead to significant cost savings and enhanced operational efficiency. Recent industry reports indicate that companies implementing advanced evaporator technologies, such as those used in thermal and mechanical vapor recompression, can reduce energy consumption by 20-30%. This reduction not only lowers operational costs but also minimizes environmental impact, aligning with the increasing focus on sustainability in manufacturing.

One key area of economic benefit is the reduction in water usage. According to a study from the Industrial Water Conference, industries are facing stricter regulations on water usage and discharge. By adopting efficient evaporator systems, companies can reclaim and recycle up to 75% of their process water, leading to substantial savings on water procurement and treatment costs. This not only boosts profitability but also ensures compliance with environmental regulations.

**Tips:** When considering an evaporator for your facility, evaluate the total cost of ownership rather than just the initial purchase price. Assess factors such as maintenance costs, energy efficiency, and potential downtime. Additionally, collaborating with engineers during the selection process can help optimize system design for more significant cost savings and improved performance, ensuring your investment pays off in the long run.

Top 10 Benefits of Using Luwa Evaporator for Your Industrial Processes

Environmental Impact and Sustainability in Luwa Evaporator Usage

The use of evaporators in industrial processes can significantly contribute to environmental sustainability. These systems not only enhance efficiency but also minimize the ecological footprint of operations. By optimizing the concentration and purification processes, evaporators reduce the volume of waste generated, which is crucial in achieving a more sustainable production cycle. The ability to recycle process water and recover valuable components makes them an essential tool in promoting circular economy principles.

Moreover, modern evaporators are designed with energy efficiency in mind. They utilize advanced heat recovery technologies that minimize energy consumption and reduce greenhouse gas emissions. This results in a lower carbon footprint, aligning industrial practices with global sustainability goals. The commitment to environmental responsibility is reflected in the way these systems operate, often incorporating automation and precision controls that lead to reduced resource usage and waste generation. By focusing on sustainable practices, industries can enhance their operational efficiency while contributing to a healthier planet.

Versatility of Luwa Evaporators Across Different Industries

The versatility of evaporators in industrial processes cannot be overstated, as they play a crucial role across a variety of sectors. From food processing to chemical manufacturing, the ability of these systems to efficiently separate liquids from solids allows for enhanced operational efficiency and product quality. According to the International Journal of Food Engineering, evaporators can help reduce processing time by up to 30%, which significantly cuts down energy consumption and costs in large-scale operations.

In the pharmaceuticals industry, the need for precise and consistent thermal management is paramount. Advanced evaporator systems provide the capability to control temperatures within strict parameters, ensuring that sensitive compounds are handled correctly. A report by the Pharmaceutical Manufacturing Association noted that implementing efficient evaporative techniques can enhance yield rates by as much as 20%, underlining the importance of integrating versatile evaporators in modern production lines.

Moreover, the adaptability of evaporators extends to their design configurations, which can be tailored to accommodate various feed materials and processing requirements. Industries such as textiles and paper manufacturing have reported successful implementations of custom evaporator solutions, which have led to increased production capacities and reduced waste by approximately 15%, as published in the Journal of Industrial Ecology. This flexibility not only improves resource efficiency but also supports sustainable practices across multiple manufacturing domains.