Employment Application Apply

Top 10 Benefits of Luwa Thin Film Evaporator for Industrial Applications?

In the industrial sector, efficiency and reliability are crucial. The "luwa thin film evaporator" stands out as a leading solution for processing. With its innovative design, it optimizes thermal efficiency, making it ideal for various applications. According to industry reports, thin film technology can improve evaporation rates by up to 40%. Such advancements can significantly reduce energy costs.

Industrial applications have become more demanding. Manufacturers are looking for ways to enhance production while minimizing waste. The "luwa thin film evaporator" addresses these challenges. Its ability to process heat-sensitive products without degradation is noteworthy. This feature is vital for maintaining product quality. However, not all organizations have adopted this technology. Some may still rely on traditional methods, which could lead to inefficiencies.

The economic implications are substantial. A report by the International Energy Agency highlights that optimizing evaporation processes can save industries millions annually. Still, organizations must consider the initial investment. Transitioning to advanced technologies requires careful planning. As businesses weigh these factors, the "luwa thin film evaporator" offers an appealing balance of performance and return on investment. The journey to modernization is not without challenges, but the benefits are compelling.

Overview of Luwa Thin Film Evaporator Technology

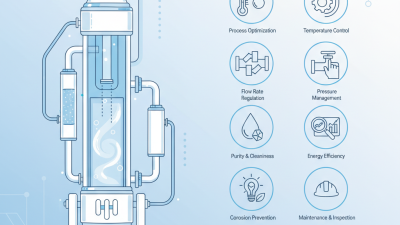

The Luwa thin film evaporator technology is a cutting-edge solution for industrial applications. It efficiently separates and concentrates liquids. This technology utilizes a thin film of liquid that flows down a heated surface. It ensures even heat distribution and minimizes thermal degradation. The design reduces the evaporation time significantly.

The evaporator's compact design saves valuable floor space. It requires less maintenance compared to traditional evaporators. Furthermore, it can handle various feed products. This flexibility makes it suitable for many industries, including food and chemicals. However, users should consider the initial investment needed for installation.

Tips for optimal use include monitoring the feed rate closely. Adjustments might be necessary based on the product's viscosity. Regular inspection of the heating surfaces can prevent issues. Efficient operation depends on maintaining the right temperatures. Inconsistent temperatures may reduce efficiency.

Key Advantages for Industrial Applications

Luwa thin film evaporators offer significant advantages for various industrial sectors. These systems excel in enhancing thermal efficiency, resulting in lower energy consumption. Reports indicate that companies using thin film technology can achieve up to 30% energy savings compared to traditional methods. This improvement is essential as energy costs continue to rise globally.

Another major benefit is the reduction in product degradation. The short residence time in the evaporator minimizes the thermal exposure of sensitive materials. Studies show that this can lead to 25% higher yield rates in certain applications. Furthermore, the compact design occupies less floor space, allowing facilities to optimize their production layout effectively.

Tip: Regular maintenance is crucial. Keeping the evaporator clean helps maintain efficiency and prolong lifespan.

Efficiency is not the only focus. Some users find it challenging to adapt to the technology initially. The learning curve can be steep. Operators need thorough training to maximize the system's potential. Similarly, while many enjoy automation features, they sometimes overlook manual controls, which can be essential during troubleshooting.

Tip: Encourage operators to experiment with settings. This hands-on practice fosters a deeper understanding of the equipment.

Energy Efficiency and Cost-Effectiveness

Energy efficiency plays a crucial role in industrial processes. Thin film evaporators are gaining attention for their remarkable performance. These systems reduce energy consumption significantly. According to recent reports, these evaporators can achieve energy savings of up to 30%. This reduction is vital in light of rising energy costs worldwide.

Cost-effectiveness is another major advantage. Implementing thin film evaporators can result in lower operational expenses. Industries that adopt these systems often report faster payback periods. Some studies indicate returns on investment (ROI) can occur within 1-3 years. However, installation costs can be a barrier for some companies. That’s worth considering during initial evaluations.

Additionally, the efficiency of these evaporators can vary based on the application. Not all processes benefit equally. Companies must assess their unique needs. A thorough analysis may reveal potential drawbacks or limitations. Relying solely on efficiency claims without due diligence could lead to unexpected challenges. Understanding these nuances is essential for making informed decisions.

Top 10 Benefits of Luwa Thin Film Evaporator for Industrial Applications

| Benefit | Description | Impact on Efficiency |

|---|---|---|

| Energy Efficiency | Optimizes energy consumption through advanced heat transfer technology. | Reduces operational costs significantly. |

| Cost-Effectiveness | Lower capital and operational expenditures compared to traditional methods. | Improves ROI for industrial applications. |

| Compact Design | Space-saving design suitable for limited space installations. | Facilitates integration into existing setups. |

| High Product Quality | Maintains product integrity through precise temperature control. | Enhances product quality and customer satisfaction. |

| Versatility | Suitable for a variety of applications including food, pharmaceuticals, and chemicals. | Broadens operational capabilities. |

| Reduced Waste | Minimizes product losses during evaporative processes. | Cost savings and sustainable practices. |

| Shorter Processing Times | Increases throughput with faster evaporation rates. | Boosts production efficiency. |

| Lower Operating Temperatures | Operates at lower temperatures, preserving heat-sensitive materials. | Enhances the quality of sensitive products. |

| Automated Controls | Incorporates advanced automation for precise control. | Reduces labor costs and minimizes human error. |

| Easier Maintenance | Simplified cleaning and maintenance protocols. | Lowers downtime and maintenance costs. |

Improved Product Quality and Consistency

Improved product quality and consistency are essential in industrial applications. The Luwa Thin Film Evaporator excels in achieving these goals. By creating a controlled environment, it minimizes product degradation. This leads to a purer end product with fewer impurities. Consistency is key in production, and this evaporator delivers. Manufacturers report significantly reduced variations in product characteristics.

Tips for maintaining quality include regular calibration of the equipment. Accurate settings enhance the uniformity of the final product. Monitoring the temperature and pressure closely is also crucial. Small fluctuations can impact quality over time.

It's essential to assess and reflect on the operational aspects. Sometimes, an unexpected change in raw materials can affect processes. Regular reviews can identify potential issues early. Manufacturers should remain adaptable to maintain high standards.

Versatility in Processing Various Materials

The Luwa thin film evaporator stands out in industrial applications for its versatility. It efficiently processes a wide variety of materials, including heat-sensitive substances. This ability to handle diverse feedstocks is essential in many industries, particularly in food and pharmaceuticals. For instance, reports indicate that nearly 70% of industries favor equipment capable of multi-material processing. This flexibility helps manufacturers optimize their processes.

Thin film evaporators operate at lower temperatures and short residence times. This minimizes degradation of sensitive materials. A recent study highlighted that these evaporators can improve yield by up to 30% in certain applications due to this gentle processing. However, not all materials perform well under thin film processing. Some may require adjustments or even alternative approaches.

While the advantages are clear, challenges remain. Operators must ensure proper parameters for each material to avoid issues. Additionally, maintenance requirements can vary with the type of substance being processed. Industry data shows that neglecting equipment upkeep can lead to a 15% drop in efficiency. Balancing these factors is crucial for optimal performance in real-world applications.

Related Posts

-

Top 10 Benefits of Thin Film Evaporators for Efficient Distillation Processes

-

Why Choose a Luwa Thin Film Evaporator for Your Industrial Process Needs

-

What is a Thin Layer Evaporator and How Does It Work

-

What is a VTA Thin Film Evaporator and How Does It Work

-

Top 10 Tips for Using a White Film Evaporator Effectively

-

How to Choose the Best Horizontal Thin Film Evaporator for Your Needs