Employment Application Apply

Top Benefits of Using Pfaudler Wiped Film Evaporator in Industrial Applications?

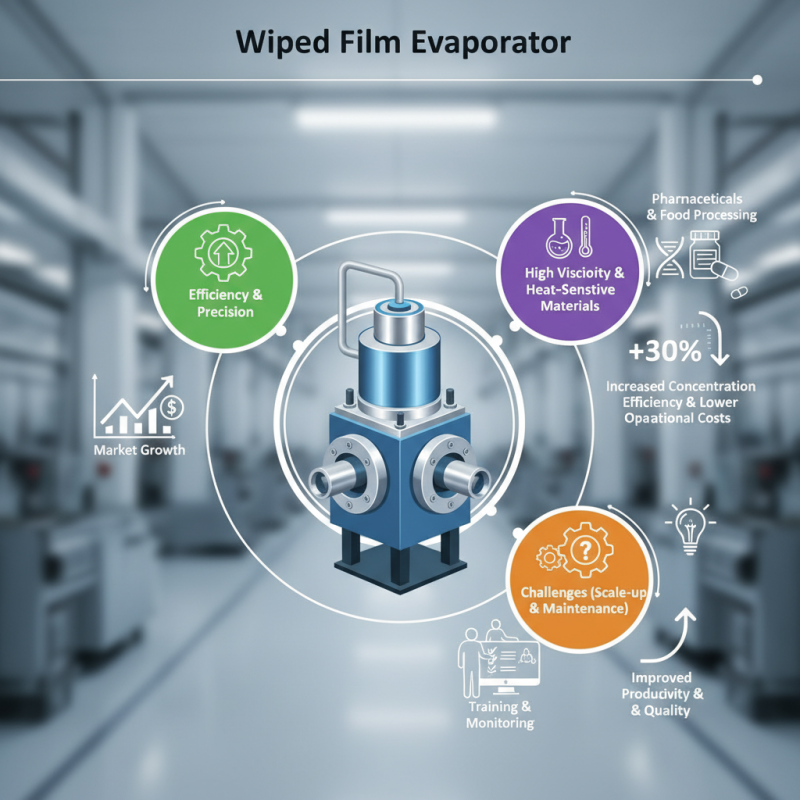

In today’s industrial landscape, efficiency and precision are paramount. The Pfaudler wiped film evaporator stands out as a critical tool for optimizing production processes. According to a report by Research and Markets, the global evaporator market is projected to reach $5.2 billion by 2026, highlighting the growing demand for advanced evaporation technologies.

The Pfaudler wiped film evaporator is designed for high viscosity and heat-sensitive materials. Its ability to maintain product integrity while enhancing evaporation rates is essential for industries like pharmaceuticals and food processing. Specific applications show that using wiped film technology can increase concentration efficiency by up to 30%. This means less energy consumption and lower operational costs.

However, not all processes benefit equally from this technology. Some users face challenges in scale-up and maintenance. These hurdles stress the importance of thorough training and consistent monitoring. The Pfaudler wiped film evaporator requires a balanced approach to maximize its advantages while addressing potential drawbacks. Embracing such technology, industries can improve productivity without compromising quality.

Key Features of Pfaudler Wiped Film Evaporators in Industry

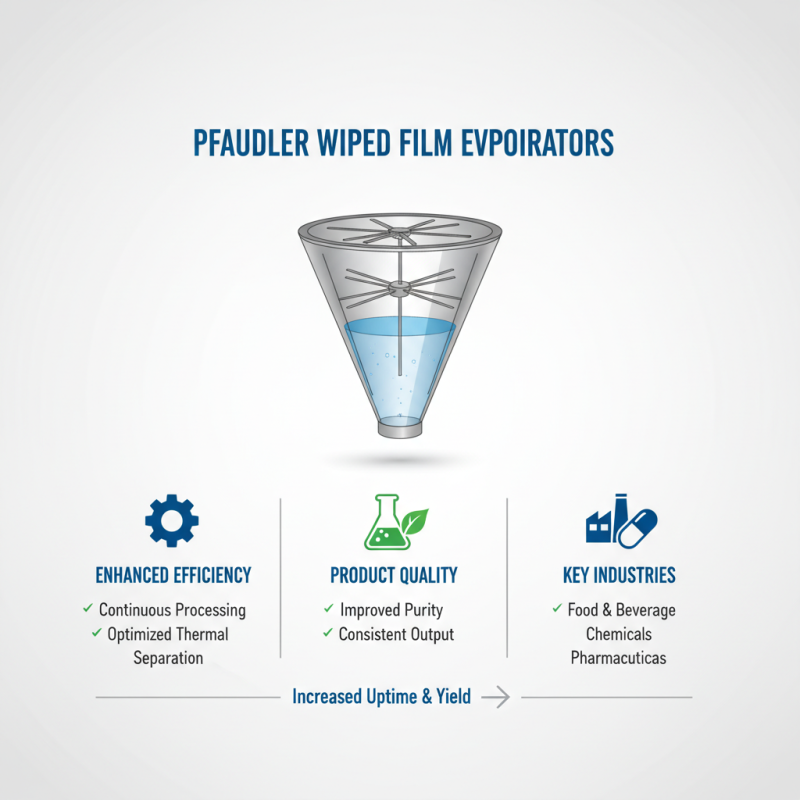

Pfaudler wiped film evaporators are crucial in various industrial applications. These systems enhance operational efficiency and product quality. Their design allows for continuous processing and effective thermal separation. This is vital in industries such as food, chemicals, and pharmaceuticals.

One standout feature is their ability to handle viscous materials. According to recent industry reports, up to 80% of challenges in evaporation occur with high-viscosity feeds. Wiped film technology minimizes thermal degradation. This addresses the sensitivity of heat-sensitive compounds. The effective heat transfer mechanism also reduces energy consumption by up to 30%.

Moreover, these evaporators offer straightforward maintenance. However, some users report challenges in achieving optimal flow rates. Each application may require specific adjustments. This can lead to trial and error, which some find frustrating. Despite this, the benefits often outweigh the drawbacks, especially when refining complex formulations. Evaporation efficiency improves, potentially increasing yield and profitability.

Efficiency Advantages of Wiped Film Evaporation in Manufacturing Processes

Wiped film evaporation is a powerful technique in manufacturing. It enhances efficiency in various industrial processes. This method effectively removes solvents, concentrating solutions with precision. The equipment operates at low temperatures, minimizing thermal degradation of sensitive materials. This is important for maintaining product quality.

One notable aspect is its ability to handle viscous fluids. Traditional evaporation methods may struggle with thick liquids, but wiped film systems excel. These systems ensure uniform heating and reduce residence time. As a result, energy consumption often decreases. Companies see significant cost savings when implementing this technology.

However, challenges remain in optimizing the process. Operators must carefully monitor parameters to avoid issues like fouling. Sometimes, the initial setup can be complex, requiring skilled personnel. Despite these hurdles, the benefits often outweigh the drawbacks. Embracing such techniques can lead to remarkable improvements in productivity and product integrity.

Application Areas Where Pfaudler Wiped Film Evaporators Excel

Wiped film evaporators shine in various industrial settings. They find success in pharmaceutical, food processing, and chemical industries. According to industry reports, these evaporators achieve high efficiency and product purity. They can handle viscous materials, which other evaporators often struggle with. This versatility makes them indispensable for many processes.

In pharmaceutical applications, wiped film evaporators excel in separating volatile compounds. They are essential for concentrating API (active pharmaceutical ingredients). Market research shows that the demand for efficient evaporation techniques in this field is expected to grow. This growth is driven by stringent quality regulations and the need for higher yields.

Tips: When selecting an evaporator, consider the thermal stability of your materials. Also, review past performance data to find the right model. Each application may require adjustments for optimal results. Acknowledging the limitations of wiped film technology is vital. Not every process will suit its design, leading to inefficiencies or product loss.

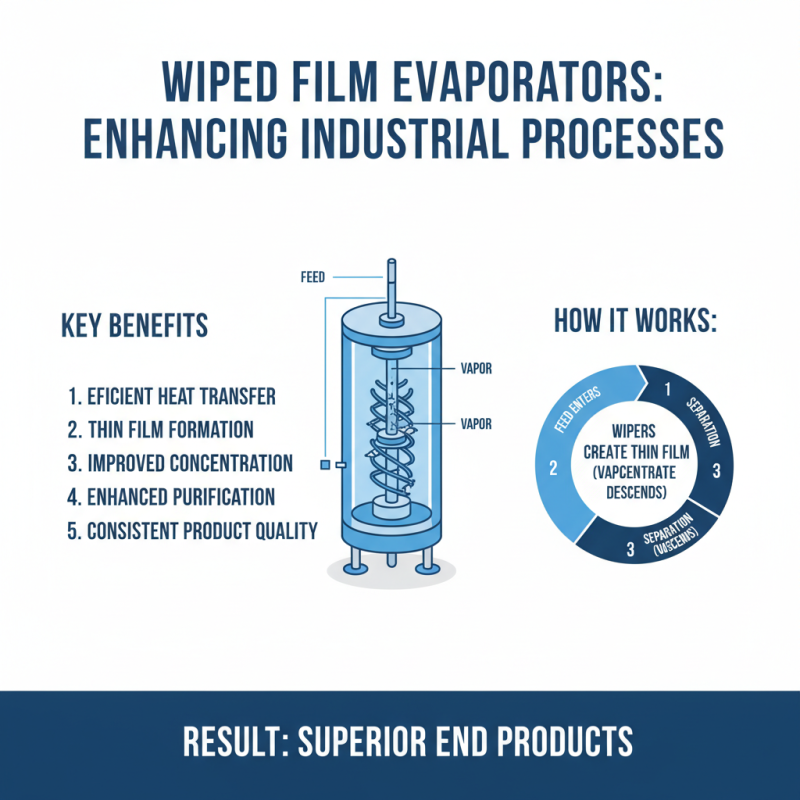

Impact on Product Quality and Consistency in Industrial Applications

Wiped film evaporators are essential in many industrial processes. They play a crucial role in enhancing product quality. By providing efficient heat transfer and thin film formation, these systems improve concentration and purification. The result is a higher quality end product. Consistency becomes easier to achieve with controlled evaporation rates.

However, challenges can arise. Variations in feed properties can affect the process. Even minor fluctuations may lead to inconsistent results. It is vital to monitor parameters closely. Maintaining a stable environment is key for optimal performance. Adjustments may be necessary to overcome any unexpected issues during operation. Regular equipment maintenance also helps minimize risks.

The impact on product quality cannot be understated. Consistent results lead to greater customer satisfaction. High-quality products are more competitive in the market. Nevertheless, the path to perfection is not easy. Continuous improvement and adaptation are crucial. There's always room for reflection and enhancement in the process. Embracing this mindset can lead to ongoing success in industrial operations.

Cost-Effectiveness of Using Pfaudler Wiped Film Evaporators in Production

The cost-effectiveness of utilizing wiped film evaporators in production is noteworthy. These systems are optimized for thermal sensitivity, allowing efficient separation of components. According to industry reports, using wiped film technology can reduce energy consumption by up to 30%. Companies can save on operational costs significantly when processing heat-sensitive materials.

The initial investment may seem high. However, the long-term savings and increased efficiency often outweigh the upfront costs. Data shows that facilities using this technology can enhance throughput by 25% compared to traditional methods. This increase not only boosts productivity but also improves profit margins.

Moreover, maintenance costs can also be lower. The efficient design of wiped film evaporators minimizes wear and tear. Yet, operators may encounter challenges. Training staff to operate these systems properly is crucial. Mistakes can lead to inefficiencies and increased downtime. Therefore, continuous improvement and employee training should be focal points in maximizing benefits.

Cost-Effectiveness of Using Wiped Film Evaporators in Production

This chart illustrates the cost savings and operational efficiency achieved through the use of wiped film evaporators in industrial applications. The data reflects potential savings on energy, maintenance, and material usage compared to traditional evaporation methods.

Related Posts

-

Top 10 Benefits of Using Luwa Evaporator for Your Industrial Processes

-

Top 10 Benefits and Applications of Pope Wiped Film Evaporator Technology

-

Top 10 Tips for Using a White Film Evaporator Effectively

-

What is a Thin Layer Evaporator and How Does It Work

-

Why Choose a Luwa Thin Film Evaporator for Your Industrial Process Needs

-

How to Optimize Your WFE Evaporator for Maximum Efficiency and Performance