Employment Application Apply

Top Benefits of Pfaudler Wiped Film Evaporators for Industrial Applications?

In today's industrial landscape, efficiency and reliability are paramount. The Pfaudler wiped film evaporator stands out as a crucial technology in enhancing chemical processes. According to a 2022 industry report by the International Journal of Food Engineering, evaporators improve process efficiency by 30% in many applications. This data underscores the importance of advanced machinery in modern manufacturing.

Dr. Emily Tran, a recognized authority in thermal separation technologies, emphasizes, "The Pfaudler wiped film evaporator revolutionizes how industries approach complex liquid separations." This statement reflects the pivotal role these evaporators play in various sectors, including food, pharmaceuticals, and chemicals.

While the benefits are clear, challenges exist. Not every facility is equipped to handle the nuances of such advanced technology. Understanding the installation and operational requirements of the Pfaudler wiped film evaporator is essential. Without proper integration, the potential gains may not be realized. Industry players must carefully consider their capabilities before implementation.

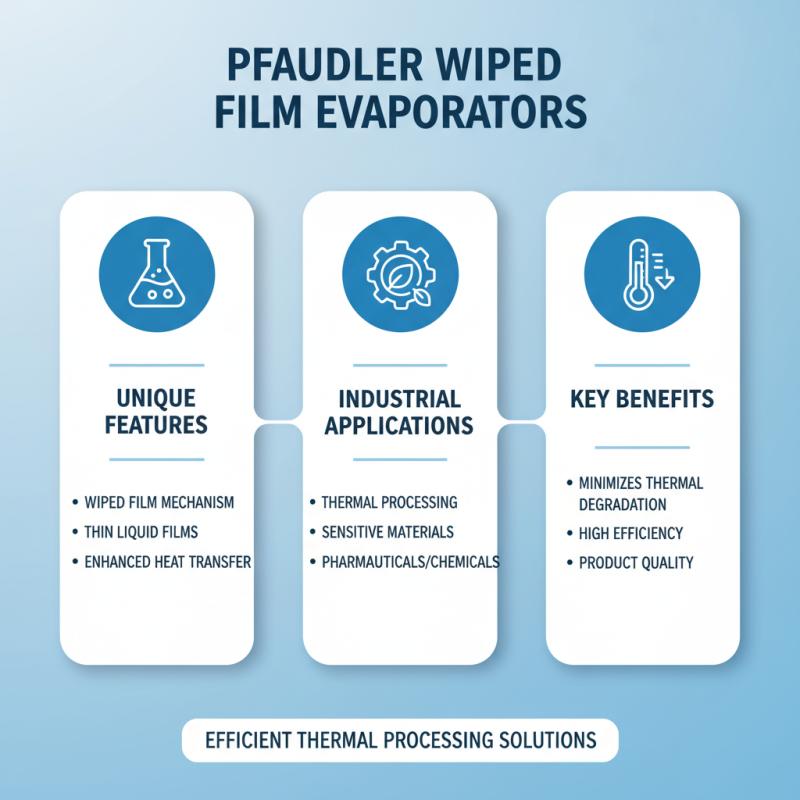

Key Features of Pfaudler Wiped Film Evaporators

Pfaudler wiped film evaporators offer unique features suited for various industrial applications. Their design allows for efficient thermal processing of sensitive materials. The wiped film mechanism ensures that thin liquid films are formed, enhancing heat transfer. This design minimizes thermal degradation.

Another key feature is their ability to handle high viscosity fluids. Many industrial processes involve thick substances that traditional evaporators struggle with. These evaporators are equipped to manage such challenges. They can process a wide range of materials, making them versatile.

Maintenance is a consideration. While some users report ease of cleaning, others find it requires more effort than expected. The balance between efficiency and upkeep is not always straightforward. Overall, these evaporators present a mix of advantages and challenges that industries must navigate.

Advantages in Process Efficiency for Industrial Applications

Wiped film evaporators are gaining traction in industrial applications due to their impressive efficiency in heat-sensitive processes. According to a recent industry report, such systems can achieve evaporation rates up to 50% higher than conventional methods. This makes them suitable for thermal-sensitive materials often found in food, pharmaceuticals, and chemical industries.

Process efficiency is a key advantage. Wiped film evaporators continuously remove vapor, minimizing residence time and thermal degradation. This is crucial for products that require delicate handling. Optimizing energy consumption is also vital. Reports indicate a reduction in operational costs by 30%. This is significant for companies striving to enhance profitability while maintaining quality.

Tips: Regular maintenance can prevent inefficiencies. Check for clogging in the wiping mechanism. Also, consider using automation for monitoring temperature and pressure during operations. This ensures optimal performance.

Efficiency isn’t the sole focus. User feedback indicates that initial setup can be challenging. Some operators find it difficult to calibrate properly. Neglecting to fine-tune settings may lead to suboptimal results. Revisit and adjust your parameters periodically for the best outcomes.

Impact on Product Quality and Consistency

Wiped film evaporators play a crucial role in maintaining product quality in various industrial applications. Their design promotes efficient heat transfer. This helps ensure that sensitive compounds remain intact during evaporation. Consistency is vital when producing high-quality goods. A small variation in temperature can impact taste and efficacy. The wiped film process minimizes this risk.

Many industries benefit from this technology. For example, food processing relies on precise evaporative techniques. The equipment can handle viscous materials easily, which is essential for concentrated products. However, not all implementations lead to flawless results. Operators must continually monitor conditions to avoid overheating or improper film thickness. This often requires careful tuning and adjustments.

Quality control remains a challenge. Even with advanced equipment, minor discrepancies are possible. Regular maintenance and calibration are crucial for consistent performance. While wiped film evaporators can enhance quality, companies must remain vigilant. They should foster a culture of constant improvement. This ensures that every batch meets the desired standards.

Benefits of Energy Savings and Sustainability

Wiped film evaporators are becoming a popular choice in industrial applications. One significant advantage is energy savings. These systems efficiently remove solvent from mixtures, minimizing energy consumption. With less energy usage, companies can lower their operating costs.

Sustainability is another crucial benefit. Efficient evaporators reduce greenhouse gas emissions. By using less energy, industries can positively impact the environment. Companies are increasingly driven to adopt eco-friendly practices.

**Tip:** Regular maintenance of equipment can enhance energy efficiency. A clean system operates better, reducing waste.

The technology promotes a more sustainable manufacturing process. However, industries still face hurdles. High initial costs can deter investments in better equipment. Companies must weigh these costs against long-term savings.

**Tip:** Conduct a detailed cost-benefit analysis before upgrading. Assess both immediate impacts and future savings.

Investing in wiped film evaporators can lead to substantial returns. Yet, reflection on energy practices is vital for true sustainability.

Applications in Various Industries and Materials

Wiped film evaporators have versatile applications across various industries.

In food processing, they efficiently concentrate flavors and remove solvents. Their ability to handle heat-sensitive materials makes them ideal for delicate substances.

For instance, in the dairy industry, they help create high-quality milk powders without compromising nutritional content.

In the pharmaceutical industry, wiped film evaporators are crucial for producing essential active ingredients. They effectively concentrate solutions while ensuring product integrity.

This process is vital for maintaining therapeutic effectiveness. Moreover, in the petrochemical sector, these evaporators play a significant role in refining complex mixtures.

They enhance separation efficiency and reduce processing times, which can significantly impact production costs.

Despite their advantages, challenges remain. The design must be meticulously tailored to each application. This requires careful consideration of temperature and pressure parameters.

Unanticipated issues can arise, such as fouling or inadequate evaporation rates. Continuous improvement and adaptation are key to overcoming these hurdles.

Industries must remain diligent in monitoring and refining their processes.

Related Posts

-

Top 10 Benefits of Thin Film Evaporators for Efficient Distillation Processes

-

Top 10 Benefits and Applications of Pope Wiped Film Evaporator Technology

-

What is a Thin Layer Evaporator and How Does It Work

-

Top 10 Tips for Using a White Film Evaporator Effectively

-

Why Choose a Luwa Thin Film Evaporator for Your Industrial Process Needs

-

What is a White Film Evaporator and How Does It Work?