Employment Application Apply

Top 10 Benefits of Thin Film Evaporators for Efficient Distillation Processes

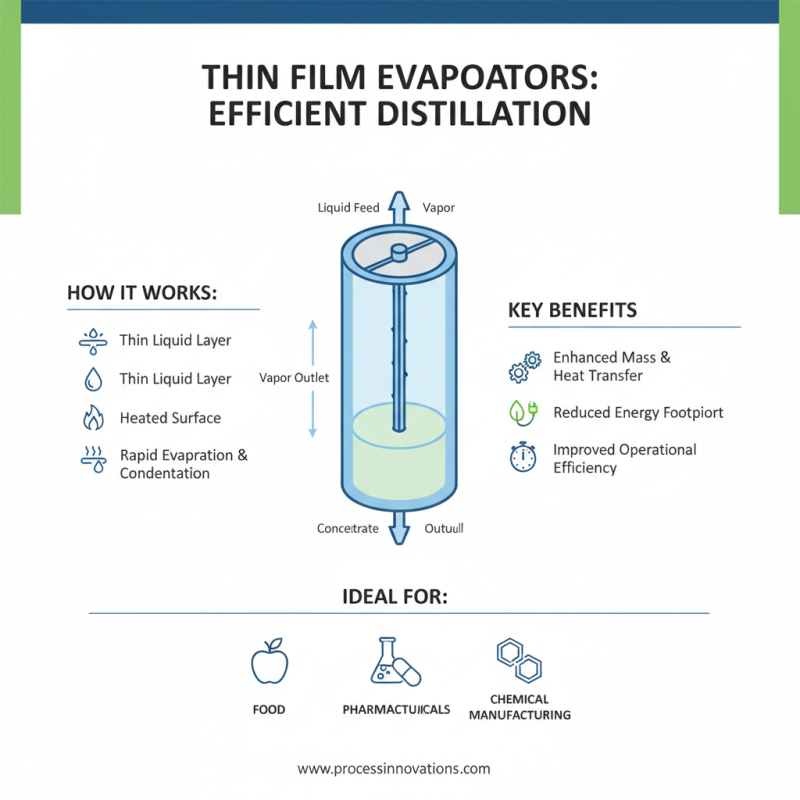

In the realm of distillation processes, the efficiency and effectiveness of the equipment used can significantly impact production outcomes. One of the most innovative and effective technologies in this field is the thin film evaporator. This unique system operates by spreading liquid across a heated surface, allowing for rapid evaporation and offering major advantages over traditional distillation methods. The thin film evaporator’s design minimizes thermal degradation and maximizes evaporation rates, making it an indispensable tool for industries looking to enhance their operational efficiency.

By leveraging the benefits of thin film evaporators, manufacturers can achieve higher purity levels in their distilled products while reducing energy consumption and processing times. These evaporators are particularly effective for heat-sensitive materials, ensuring that quality is maintained without compromising on throughput. As industries continue to evolve and demand more sustainable and efficient processing solutions, the role of thin film evaporators becomes increasingly critical. This article delves into the top ten benefits of thin film evaporators, highlighting their significance in optimizing distillation processes across various sectors.

Understanding Thin Film Evaporators in Distillation Processes

Thin film evaporators are specialized devices used in distillation processes, providing an efficient method for separating liquid mixtures. These systems operate by forming a thin layer of liquid on a heated surface, allowing for quick evaporation and condensation. This design enhances mass and heat transfer, resulting in improved operational efficiency and a reduced energy footprint, making them an ideal choice for various industries, including food, pharmaceuticals, and chemical manufacturing.

One of the key advantages of thin film evaporators is their ability to handle heat-sensitive materials without degrading the product’s quality. The short residence time of the liquid on the heated surface minimizes thermal exposure, which is crucial for preserving volatile components. Additionally, thin film evaporators can operate under vacuum conditions, further lowering boiling points and enhancing efficiency.

**Tips:** When considering the implementation of thin film evaporators in your process, it's essential to assess the specific thermal tolerance of the materials involved. Regular maintenance of the equipment can also ensure consistent performance and extend its lifespan. Moreover, optimizing the operating parameters—such as temperatures, flow rates, and pressure—can lead to significant improvements in separation efficiency and product yield.

Key Advantages of Using Thin Film Evaporators for Efficiency

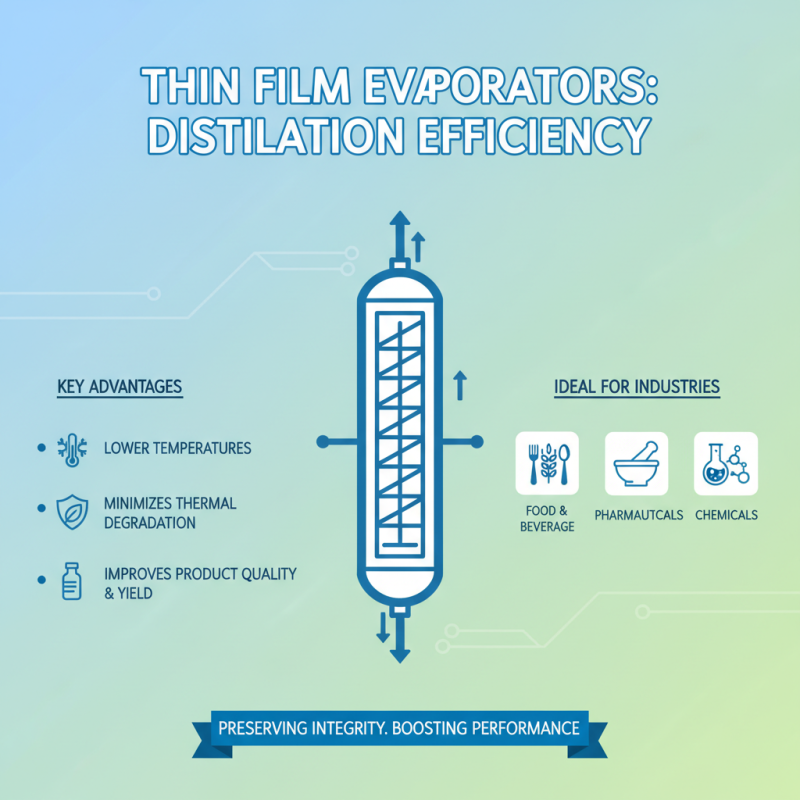

Thin film evaporators are increasingly recognized for their role in enhancing the efficiency of distillation processes across various industries. One of the key advantages of using these systems lies in their ability to operate at lower temperatures, which minimizes thermal degradation of sensitive materials. This capability is particularly beneficial for the food, pharmaceutical, and chemical sectors, where preserving product integrity is crucial. By reducing heat exposure, thin film evaporators help maintain quality while also improving yield.

Another significant benefit is the enhanced mass and heat transfer characteristics of thin film evaporators. The design allows for a higher surface area to volume ratio, which promotes rapid evaporation and efficient separation of components. This efficiency not only speeds up processing times but also reduces energy consumption, making it a more sustainable option compared to traditional distillation methods. Furthermore, the continuous processing capabilities of thin film evaporators enable higher throughput, making them ideal for large-scale operations. As industries strive for innovation and efficiency, the adoption of thin film technology is proving to be a key factor in optimizing distillation processes.

Mechanisms of Heat Transfer in Thin Film Evaporators

Thin film evaporators are increasingly gaining recognition in the industry due to their efficient heat transfer mechanisms, which are vital for optimizing distillation processes. One of the primary mechanisms at play is the film formation process, where the liquid feed is introduced onto a heated surface. As the film of liquid spreads and thins out, a larger surface area is exposed to heat, enhancing the rate of evaporation. According to a report by the International Journal of Heat and Mass Transfer, thin film evaporators can achieve heat transfer coefficients up to 10 times greater than traditional evaporators, resulting in significant reductions in energy consumption.

Additionally, the design of thin film evaporators facilitates effective heat transfer through controlled thermal gradients. The use of rotating devices often results in mechanical agitation of the film, promoting turbulence and improving both mass and heat transfer rates. As noted in a study by the Chemical Engineering Research and Design Journal, the rotational speed can be precisely adjusted to optimize evaporation rates, leading to improved overall process efficiency. These innovations not only enhance thermal transfer but also contribute to the minimization of thermal degradation of sensitive materials, which is crucial in industries such as pharmaceuticals and food processing.

Applications of Thin Film Evaporators in Various Industries

Thin film evaporators are instrumental in various industries, significantly enhancing the efficiency of distillation processes. Their unique design allows for rapid heat transfer and minimized residence time, making them ideal for sensitive materials. In the food and beverage sector, thin film evaporators are frequently used for concentrating fruit juices and dairy products, ensuring the preservation of flavor and nutritional value. Similarly, in the pharmaceutical industry, they play a critical role in concentrating active ingredients while maintaining their purity and efficacy.

In addition to these applications, thin film evaporators are also utilized in the chemical and petrochemical industries for the recovery of solvents and valuable components from reaction mixtures. Their ability to handle viscous liquids makes them particularly valuable in these sectors, where efficiency and product quality are paramount.

**Tips:** When considering the implementation of thin film evaporators, assess the thermal sensitivity of your materials and the required throughput. This ensures that you choose the appropriate system configuration to meet your specific distillation needs. Regular maintenance is also essential to keep the evaporation process running smoothly, thereby extending the lifespan of the equipment and enhancing its performance.

Top 10 Benefits of Thin Film Evaporators for Efficient Distillation Processes

This chart illustrates the top 10 benefits of thin film evaporators in efficient distillation processes, showcasing how each benefit contributes to overall performance and functionality across various industries.

Cost-Benefit Analysis of Thin Film Evaporators vs. Traditional Methods

The cost-benefit analysis of thin film evaporators compared to traditional distillation methods reveals significant advantages for industrial processes. Thin film evaporators operate at lower temperatures and pressures, which not only enhances the efficiency of heat transfer but also minimizes energy consumption. This leads to lower operational costs in the long run. Additionally, the ability of thin film evaporators to process high-viscosity materials without fouling means that they require less maintenance and downtime than traditional methods, further contributing to cost savings.

Moreover, thin film evaporators offer higher product yields by allowing for better separation of components, which translates into reduced losses of valuable materials. Traditional methods often involve longer processing times and more complex setups, leading to higher labor costs and increased risk of product degradation. With lower solvent recovery times and improved operational flexibility, industries can benefit from a quicker return on investment. Overall, the adoption of thin film evaporators can result in significant financial advantages while maintaining high levels of efficiency and product quality.