Employment Application Apply

How to Choose the Best Horizontal Thin Film Evaporator for Your Needs

The selection of an appropriate horizontal thin film evaporator is a critical decision for industries involved in liquid processing, including pharmaceuticals, food production, and chemical manufacturing. According to a recent report by Market Research Future, the global market for thin film evaporators is projected to grow at a CAGR of 7.5% over the next five years, underscoring the increasing reliance on this technology for efficient and effective separation processes. As industries seek to optimize their operations, understanding the specific requirements and capabilities of horizontal thin film evaporators becomes essential in enhancing productivity and ensuring product quality.

Dr. Emily Chen, a leading expert in thermal separation technologies, emphasizes the significance of tailored solutions, stating, "Choosing the right horizontal thin film evaporator is not just a technical choice; it hinges on a thorough understanding of your process requirements and the desired outcomes." Her insights highlight the importance of aligning equipment capabilities with operational needs. Factors such as evaporation rates, product viscosity, heat sensitivity, and energy efficiency must be considered during the selection process to achieve optimal performance.

In summary, equipping yourself with the right information and expert insights will enable you to navigate the complexities of selecting a horizontal thin film evaporator that meets your specific requirements, ultimately leading to improved operational efficiencies and reliability in your production processes.

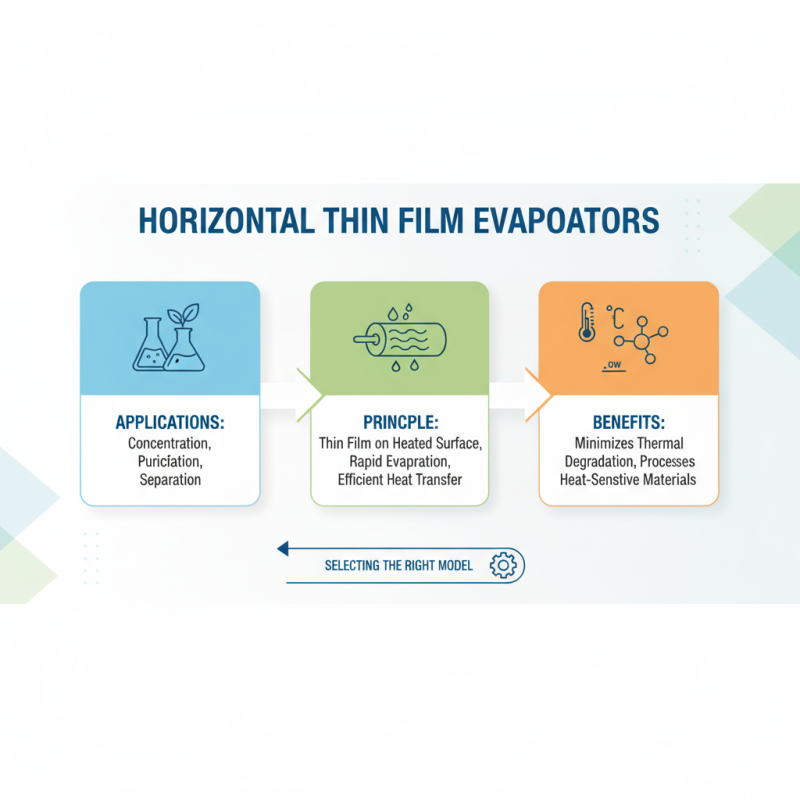

Understanding the Basics of Horizontal Thin Film Evaporators

Horizontal thin film evaporators are essential equipment widely used in various industries for concentration, purification, and separation processes. Understanding their basic principles is crucial for selecting the right model to meet specific operational needs. These evaporators operate by creating a thin film of liquid on a heated surface, allowing rapid evaporation of solvents and efficient heat transfer. This design minimizes thermal degradation of sensitive compounds, making them suitable for processing heat-sensitive materials.

The core components of a horizontal thin film evaporator include the evaporation chamber, heating system, and feed mechanism. The process begins with the introduction of the liquid feed into the chamber, where it is spread into a thin film by rotating blades or wipers. The controlled heating and vacuum conditions facilitate quick evaporation, resulting in a concentrated product. Understanding factors such as the nature of the material being processed, required end product specifications, and operational efficiency is vital in optimizing evaporator performance and ensuring suitability for specific applications.

Identifying Your Specific Needs and Requirements

When selecting the best horizontal thin film evaporator for your applications, it is crucial to begin by identifying your specific needs and requirements. Different industries have varying specifications based on the nature of the materials being processed. For instance, a report by the Chemical Engineering Research and Design Journal highlights that in the pharmaceutical sector, operating temperatures typically range between 50°C to 150°C, requiring evaporators that can efficiently handle temperature-sensitive substances. Understanding the thermal and flow characteristics of your material is vital to ensure optimal performance.

Additionally, production capacity plays a significant role in choosing the right evaporator. According to data from the International Journal of Chemical Reactor Engineering, the demand for large-scale production in the food and beverage industry is rising, with many companies requiring evaporators that can process upwards of 10,000 liters per hour. Failing to align the evaporator's capacity with production requirements can lead to inefficiencies and increased operational costs. It is also necessary to consider space constraints and installation preferences, as a properly configured system can enhance overall efficiency and productivity. By assessing these parameters, you can make a well-informed decision that meets both operational stability and efficiency.

How to Choose the Best Horizontal Thin Film Evaporator for Your Needs - Identifying Your Specific Needs and Requirements

| Parameter | Description | Optimal Range | Considerations |

|---|---|---|---|

| Feed Rate | The amount of material processed per hour. | 5 - 1000 kg/h | Match with production demands. |

| Operating Temperature | Temperature range required for evaporation. | 30 - 200 °C | Consider thermal sensitivity of products. |

| Material Compatibility | Type of materials to be processed. | Corrosive, viscous, or crystallizing | Ensure equipment material is suitable. |

| Energy Efficiency | Efficiency of heat transfer and energy use. | >80% efficiency | Lower energy costs and environmental impact. |

| Space Requirement | Available footprint for installation. | Varies with output capacity | Consider future expansion needs. |

Evaluating Key Features and Specifications

When selecting the best horizontal thin film evaporator, it is essential to thoroughly evaluate its key features and specifications. One of the most critical factors to consider is the evaporator's surface area, which directly influences evaporation efficiency. According to a report by Grand View Research, the efficiency of thin film evaporators can significantly enhance throughput, especially in industries such as pharmaceuticals and chemical processing, where precise solvent removal is paramount. A larger surface area allows for more extensive thermal exchange, thereby improving the overall operational performance.

Another crucial specification to assess is the temperature and pressure range the evaporator can handle. High-performance models can operate at elevated temperatures and vacuum conditions, which are essential for delicate materials that are susceptible to thermal degradation. A study by MarketsandMarkets highlights that optimal operational parameters can lead to energy savings of up to 30%, which makes it vitally important to select a model that aligns with specific process requirements. Additionally, understanding the materials of construction, such as stainless steel or special alloys, will impact not only the durability of the equipment but also its compatibility with various substances, ensuring efficient and safe operation over time.

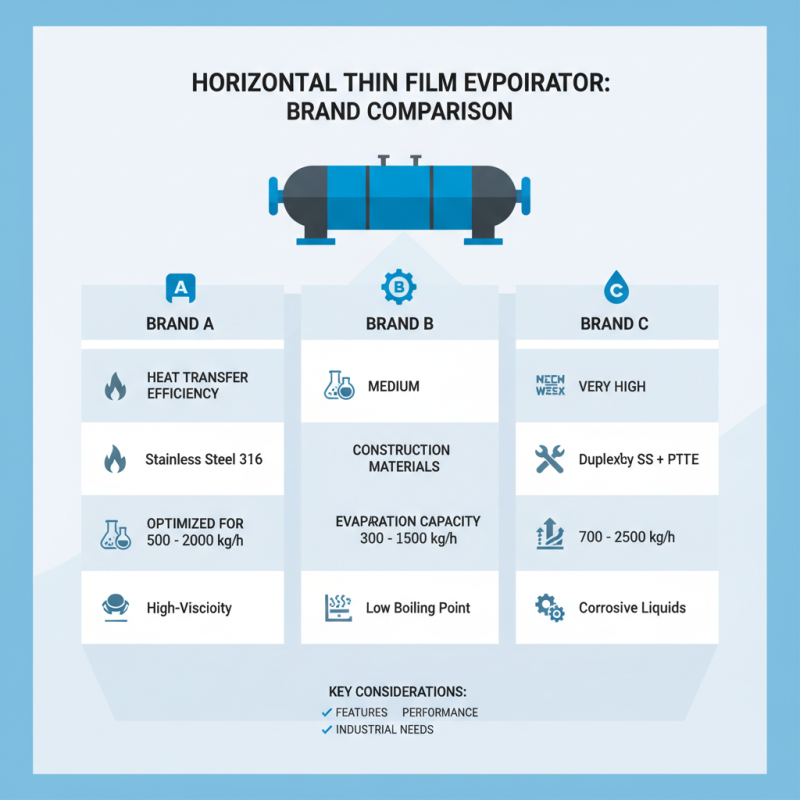

Comparing Different Brands and Models

When selecting a horizontal thin film evaporator, a vital step is to compare different brands and models based on their features and performance. Each brand offers unique specifications tailored to various industrial needs, such as heat transfer efficiency, materials of construction, and overall system design. It's crucial to assess the evaporation capacity and operational temperature ranges of different models. Some may excel in processing high-viscosity liquids, while others are optimized for lower boiling point applications.

In addition to performance, consider the maintenance requirements and associated costs of different brands. Ease of cleaning and accessibility for routine service checks can significantly affect long-term operational efficiency. Moreover, evaluating the technical support and warranty options from different manufacturers can further influence your decision. Understanding these differences allows for a more informed selection process, ensuring that the evaporator not only meets immediate operational needs but also aligns with future production goals.

Maintenance and Support Considerations for Longevity

Maintaining a horizontal thin film evaporator is crucial for ensuring its longevity and optimal performance. Regular maintenance routines should include checking for wear and tear on seals, gaskets, and bearings, which can impact efficiency and safety. According to industry data published by the International Society of Automation, routine maintenance can extend equipment lifespan by up to 30%, significantly reducing replacement costs and downtime in production processes. Additionally, keeping the evaporator's heat transfer surfaces clean is vital. Fouling can decrease the heat transfer efficiency, leading to higher energy consumption and operating costs.

Support considerations also play a significant role in the longevity of thin film evaporators. It's important to assess the availability of technical support from suppliers, including access to spare parts and expert advice. Reports from the American Society of Mechanical Engineers emphasize that upon installation, having a reliable support system in place can ensure that users can troubleshoot and resolve issues swiftly, minimizing operational disruptions. Investing in staff training for routine checks and operational best practices has been shown to increase efficiency by as much as 25%, further underscoring the need for a sustainable maintenance and support strategy.

Evaporator Maintenance Frequency vs. Longevity

Related Posts

-

Top 10 Benefits of Thin Film Evaporators for Efficient Distillation Processes

-

What is a Thin Layer Evaporator and How Does It Work

-

Top 10 Benefits of Using Luwa Evaporator for Your Industrial Processes

-

What is a VTA Thin Film Evaporator and How Does It Work

-

Top 5 Tips for Using LCI Wiped Film Evaporators Effectively

-

2025 Top Film Evaporator Technologies and Trends You Need to Know