Employment Application Apply

Why Choose a Luwa Thin Film Evaporator for Your Industrial Process Needs

In the realm of industrial processing, the choice of equipment can significantly impact efficiency and product quality. The Luwa Thin Film Evaporator stands out as a premier solution for industries requiring precise separation and concentration of substances. According to Dr. Emily Carter, an expert in thermal processing technology, "The Luwa Thin Film Evaporator is not just about functionality; it represents a leap towards achieving optimal energy efficiency and product integrity." This statement encapsulates the essence of why many manufacturers are gravitating towards this innovative technology.

Utilizing a Luwa Thin Film Evaporator allows for effective and gentle thermal treatment of heat-sensitive materials, minimizing degradation while maximizing recovery rates. The unique design facilitates a high mass transfer efficiency, making it suitable for a variety of applications, from pharmaceuticals to food processing. As industries continue to seek more sustainable and efficient processing methods, the adoption of advanced technologies like the Luwa Thin Film Evaporator becomes increasingly crucial for staying competitive.

With its capability to streamline operational processes while ensuring quality outcomes, the Luwa Thin Film Evaporator is an indispensable asset for modern industrial needs. The combination of expert engineering and cutting-edge design propels it to the forefront of evaporative technologies, addressing both current and emerging challenges in diverse sectors.

Benefits of Luwa Thin Film Evaporators in Industrial Applications

Luwa thin film evaporators are increasingly becoming the preferred choice for industrial processes due to their efficiency and versatility. One of the primary benefits of these evaporators is their ability to handle heat-sensitive materials. The thin film technology allows for a gentle and uniform heating process, which minimizes the risk of thermal degradation and ensures product quality. This characteristic is particularly beneficial in industries like pharmaceuticals, food processing, and specialty chemicals, where maintaining the integrity of delicate compounds is critical.

Another significant advantage of thin film evaporators is their high operational efficiency. These systems are designed to maximize heat transfer and minimize energy consumption, which can lead to reduced operational costs over time. The continuous operation of thin film evaporators allows for better process control and faster processing times compared to traditional evaporators. Additionally, their compact design makes them suitable for various installation setups, allowing industries to optimize their space while maintaining high throughput. This combination of efficiency, adaptability, and product safety makes thin film evaporators a valuable asset in modern industrial applications.

Key Technical Specifications of Luwa Thin Film Evaporators

When evaluating evaporators for industrial processes,

thin film evaporators stand out due to their efficient

thermal performance and ability to handle a wide range of feed materials. The key technical

specifications of thin film evaporators include their optimal operating temperature range,

which generally spans from 100°C to 300°C, allowing them to effectively

remove solvents while minimizing thermal degradation of sensitive components. Furthermore,

these evaporators typically boast high heat transfer coefficients, often exceeding

500 W/m²K, resulting in reduced residence

time and enhanced process efficiency.

Additionally, the design features of these evaporators play a crucial role in their performance.

Most thin film evaporators utilize a continuous flow system that significantly lowers the likelihood

of fouling, thereby maintaining operational efficiency. With the capacity to evaporate up to

90% of water content in a given solution, thin film

technology is especially beneficial in sectors ranging from food to pharmaceuticals, where

product quality and consistency are paramount.

Tip: When selecting a thin film evaporator, consider the

viscosity of your feed material and the specific energy requirements for your process. It’s

also advisable to engage in a thorough economic analysis; a well-chosen evaporator can lead

to costly savings by increasing throughput and minimizing energy consumption. Don't overlook

the importance of maintenance schedules to ensure long-term efficiency and reliability.

Energy Efficiency and Cost Savings with Thin Film Evaporators

Thin film evaporators have become increasingly popular in various industrial processes due to their remarkable energy efficiency and significant cost savings. According to a recent report by industry analysts, optimizing energy consumption in manufacturing can reduce operational costs by as much as 30%. This is particularly relevant for processes that require significant thermal treatments, where traditional evaporators often waste a considerable amount of heat energy. The design of thin film evaporators allows for a more efficient heat transfer process, thus reducing energy requirements during operation.

Moreover, the overall reduction in energy consumption coupled with lower maintenance costs contributes to enhanced profitability. As per analysis from the Global Industrial Evaporators Market Report, organizations adopting advanced evaporation technologies, such as thin film evaporators, can achieve ROI improvements of up to 20% over conventional systems. The reduced thermal load and increased concentration efficiency result in not only energy savings but also a more streamlined process, leading to reduced cycle times and increased production capacity. Therefore, opting for thin film evaporators can be a strategic decision for industries looking to enhance sustainability while maximizing financial performance.

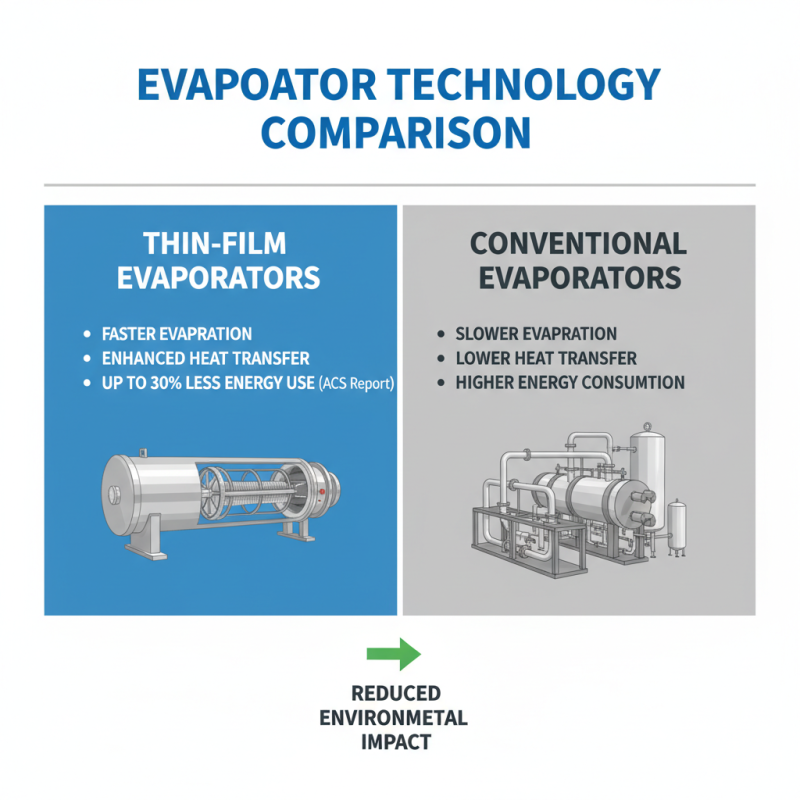

Comparative Analysis of Thin Film vs. Conventional Evaporators

When comparing thin film evaporators to conventional evaporators, several critical factors set them apart in industrial applications. Thin film evaporators utilize a different mechanism that allows for faster evaporation rates due to a reduced film thickness and enhanced heat transfer capabilities. According to a report from the American Chemical Society, thin film evaporators can achieve higher thermal efficiency, with energy consumption reduced by up to 30% compared to traditional evaporators. This reduced energy use not only lowers operational costs but also has a significant positive impact on the environmental footprint of industrial processes.

Additionally, the ability of thin film evaporators to handle heat-sensitive materials makes them particularly advantageous in applications such as pharmaceuticals and food processing. A comparative study by the International Journal of Food Engineering indicates that thin film systems can maintain product quality by minimizing thermal decomposition and reducing residence time in the evaporator. In contrast, conventional evaporators often subject products to prolonged heat, leading to potential losses in volatile compounds and degradation of sensitive ingredients. These advantages underscore why many industries are increasingly turning to thin film evaporators for efficient and effective processing solutions.

Real-World Case Studies Demonstrating Luwa Evaporators’ Effectiveness

Luwa thin film evaporators have become a cornerstone in various industrial processes due to their

efficiency and versatility. Real-world case studies have

highlighted their effectiveness across different applications, showcasing their ability to handle heat-sensitive

materials while preserving product integrity. For instance, a renowned food processing company implemented a

Luwa system to concentrate fruit juices, achieving a reduction in energy consumption by up to

30%, according to industry reports. This synergy of

efficiency and quality preservation makes these evaporators a preferred choice among manufacturers looking

to optimize their processes.

Another compelling case study involves a pharmaceutical manufacturer that saw a remarkable increase in

production speed by 50% after integrating a Luwa

thin film evaporator. By minimizing thermal degradation of sensitive compounds, the plant managed to improve

yield rates significantly. Industry analysts report that thin film technology can reduce the evaporation time

by up to

60% compared to traditional methods, enabling

more efficient batch cycles and lower operational costs.

Tip: When considering

an evaporator system, assess your specific process needs and evaluate customer case studies to understand

the transformative potential of thin film technology in your industry.

Tip: Factor in the

long-term operational savings when evaluating the initial investment of a thin film evaporator to maximize

your return on investment.

Related Posts

-

Top 10 Benefits of Thin Film Evaporators for Efficient Distillation Processes

-

What is a Thin Layer Evaporator and How Does It Work

-

Top 10 Tips for Using a White Film Evaporator Effectively

-

Top 10 Benefits and Applications of Pope Wiped Film Evaporator Technology

-

2025 Top Film Evaporator Technologies and Trends You Need to Know

-

How to Optimize Your WFE Evaporator for Maximum Efficiency and Performance