Employment Application Apply

How to Optimize Your WFE Evaporator for Maximum Efficiency and Performance

In the pursuit of operational excellence within the chemical processing industry, optimizing the performance of the WFE evaporator has become increasingly critical. According to a report by the International Society for Pharmaceutical Engineering, evaporators account for approximately 30% of energy consumption in manufacturing processes, underscoring the importance of efficiency improvements. The WFE evaporator, known for its robustness and versatility, plays a pivotal role in enhancing product purity while minimizing energy and resource usage. Consequently, improving its efficiency not only leads to cost savings but also contributes to sustainable practices within the sector.

Furthermore, recent studies highlight that optimizing WFE evaporator systems can yield energy savings of up to 20%, significantly impacting the bottom line for many facilities. As companies face rising operational costs and stringent environmental regulations, the drive for increased efficiency becomes more pronounced. Enhancements in design, maintenance, and operational parameters are essential for maximizing the performance of WFE evaporators, ultimately leading to improved throughput, reduced downtime, and a more sustainable overall process. Adopting a proactive approach to the optimization of these systems is paramount for organizations aiming to stay competitive in today's dynamic market landscape.

Overview of WFE Evaporator Systems and Their Importance

WFE (Wiped Film Evaporator) systems play a crucial role in various industrial processes, particularly in the chemical, pharmaceutical, and food industries. These systems are designed to efficiently separate volatile components from mixtures, enhancing the overall productivity and quality of products. Their ability to operate at low temperatures while minimizing thermal degradation makes WFE evaporators an essential tool for manufacturers aiming to optimize their operations.

To ensure maximum efficiency and performance of your WFE evaporator, consider implementing some essential tips. First, regularly maintain the system components to prevent wear and tear that can lead to inefficiencies. Keep the heating elements clean and monitor the seals and gaskets for any signs of wear. Second, it’s important to optimize the feed rate and temperature settings of the evaporator. An over- or under-fed system can lead to inadequate separation, thus impacting the overall yield.

Lastly, pay attention to the choice of the working fluid and the design of the evaporator. Selecting the appropriate materials that enhance thermal transfer could significantly improve the efficiency of the process. By focusing on these aspects, you can enhance the operational effectiveness of your WFE evaporator system, ensuring high-quality outcomes and maximizing your production capacity.

Evaporator Performance Metrics

Key Factors Affecting Efficiency in WFE Evaporators

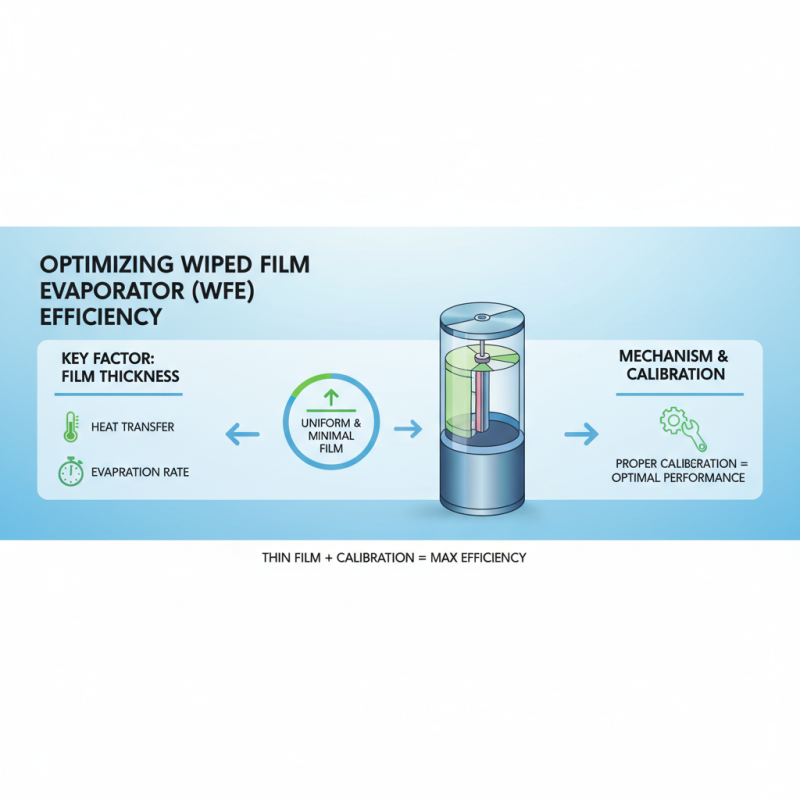

The efficiency of a WFE (Wiped Film Evaporator) can be significantly impacted by several key factors, which organizations must consider to optimize performance. One primary factor is the film thickness, which is crucial for ensuring adequate heat transfer. A uniform and minimal film thickness allows for faster evaporation rates, maximizing the surface area exposed to heat. Proper calibration of the wiping mechanism is essential to achieve this, as it directly influences the film thickness across the evaporator surface.

Another critical aspect affecting the efficiency of WFE evaporators is the operating temperature. Maintaining optimal temperature conditions enhances the volatility of the components being evaporated, thereby improving separation efficiency. However, excessive temperatures can lead to thermal degradation of sensitive materials, highlighting the need for precise temperature control. Additionally, fluctuating feed rates can disrupt the balance within the system, potentially leading to inefficient operation. Consistent feed characteristics, including flow rate and viscosity, are vital for maintaining steady state conditions, which ultimately boosts the overall efficacy of the evaporator.

Best Practices for Maintenance and Performance Enhancements

Maintaining the efficiency and performance of Water Film Evaporators (WFE) is crucial for industrial operations. Regular maintenance not only prolongs the lifespan of the equipment but also ensures optimal performance. According to a report by the International Institute of Refrigeration, proper maintenance can improve system efficiency by as much as 30%. One key practice is to conduct routine inspections of the evaporator's components, including the heat exchanger surfaces and the operation of the feedwater system. Identifying and addressing wear and tear early can prevent costly downtime and enhance overall productivity.

**Tips:** Schedule monthly maintenance checks focusing on cleaning the heat transfer surfaces. Accumulated debris can significantly hinder thermal efficiency. Also, monitor the pressure and temperature differentials regularly to detect any deviations that might indicate an inefficiency in the system.

Additionally, implementing advanced technologies such as automated monitoring systems can provide real-time data on the evaporator's performance. According to findings from the American Society of Heating, Refrigerating and Air-Conditioning Engineers, automation can yield efficiency gains exceeding 20%. Data analytics can help identify patterns that predict malfunctions, enabling proactive interventions.

**Tips:** Utilize diagnostics software to assess performance metrics and set alerts for anomalies. This approach not only refines operational efficiency but also helps optimize energy consumption, aligning with industry best practices for sustainable performance enhancements.

How to Optimize Your WFE Evaporator for Maximum Efficiency and Performance

| Parameter | Optimal Value | Frequency of Monitoring | Best Practices for Maintenance |

|---|---|---|---|

| Temperature | -10°C to -5°C | Daily | Regular calibration and sensor checks |

| Pressure | 0.5 to 1.5 MPa | Weekly | Inspect seals and gaskets for leaks |

| Flow Rate | 500 to 1000 L/h | Monthly | Clean filters and check pump performance |

| Energy Consumption | 60 to 80 kWh/day | Monthly | Perform regular energy audits |

| Maintenance Interval | Every 6 months | N/A | Comprehensive inspection and servicing |

Advanced Technologies for Optimizing WFE Evaporator Operations

Advanced technologies play a crucial role in optimizing the operations of WFE (Wiped Film Evaporator) systems, significantly enhancing efficiency and performance. One of the forefront technologies in this domain is the integration of process control automation. By utilizing real-time data analytics and feedback mechanisms, operators can continuously monitor critical parameters such as temperature, pressure, and flow rates. This automation not only helps in maintaining optimal operating conditions but also aids in quickly identifying and rectifying any deviations, thus reducing downtime and increasing overall system reliability.

In addition to automation, the implementation of advanced heat exchange materials can further improve WFE efficiency. Innovations in thermal management materials, like high-conductivity alloys and specialized coatings, can enhance heat transfer rates and minimize energy losses. These materials contribute to achieving more uniform temperature distributions within the evaporator, leading to consistent product quality and higher throughput. Furthermore, advanced software modeling tools can simulate various operational scenarios, allowing engineers to design and optimize WFE systems tailored to specific processing needs, thereby maximizing the performance of the evaporation process.

Measuring and Analyzing Efficiency Metrics in WFE Evaporators

Measuring and analyzing efficiency metrics in WFE evaporators is crucial for identifying performance bottlenecks and optimizing operational processes. One of the primary metrics to consider is overall energy consumption, which includes both direct energy costs and the thermal energy recovery rate. By conducting a thorough energy audit, operators can pinpoint specific areas where energy is lost, such as through heat transfer inefficiencies.

Implementing technologies like real-time energy monitoring systems allows operators to visualize energy flow and make data-driven decisions to enhance efficiency.

Additionally, analyzing throughput and product yield serves as fundamental indicators of evaporator performance. Tracking the amount of feed processed versus the output can reveal operational inefficiencies and guide adjustments in process parameters. Utilizing tools like statistical process control (SPC) can help in maintaining consistency in production while minimizing variations. It’s also beneficial to routinely assess the evaporator's operational stability and responsiveness to changes in feed properties, which directly impacts both efficiency and product quality.

By focusing on these metrics, operators can drive continuous improvement in WFE evaporator processes, thereby maximizing efficiency and enhancing overall performance.

Related Posts

-

2025 Top Film Evaporator Technologies and Trends You Need to Know

-

Top 5 Tips for Using LCI Wiped Film Evaporators Effectively

-

Top 10 Benefits of Thin Film Evaporators for Efficient Distillation Processes

-

What is a Thin Layer Evaporator and How Does It Work

-

Top 10 Benefits and Applications of Pope Wiped Film Evaporator Technology

-

What is a VTA Thin Film Evaporator and How Does It Work