Employment Application Apply

Top 5 Tips for Using Agitated Film Evaporators Effectively?

Agitated film evaporators have become essential in various industries, particularly food processing and pharmaceuticals. According to industry reports, the global market for evaporators is projected to grow significantly over the next few years. These devices excel in concentration and separation processes, maximizing efficiency while minimizing energy consumption.

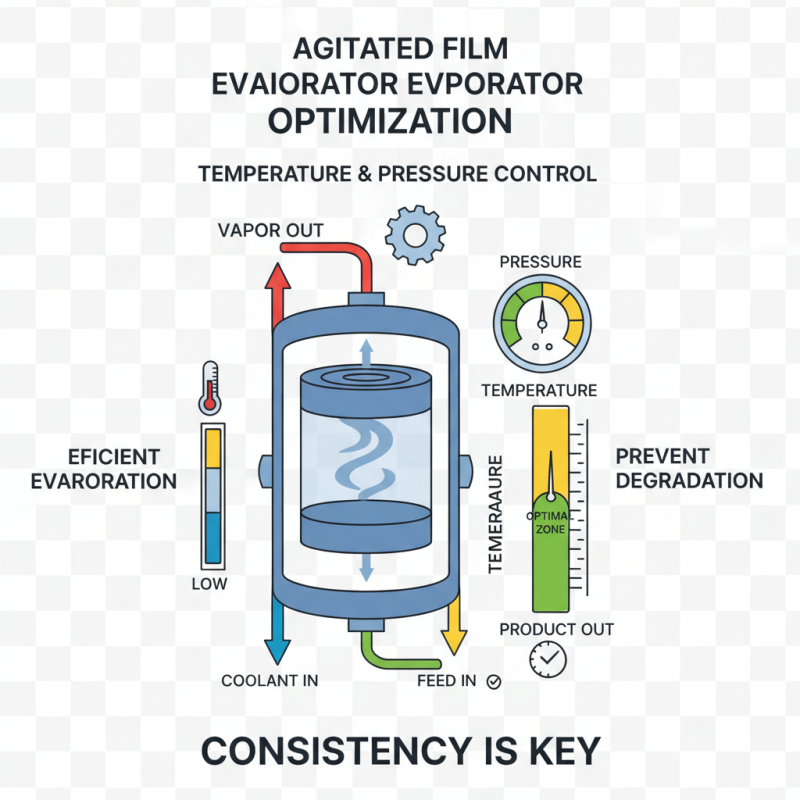

Despite their advantages, many users encounter challenges. The design and operation of an agitated film evaporator can be complex. Proper usage plays a crucial role in ensuring optimal performance. For instance, maintaining the right temperature and pressure is critical to avoid product degradation. Furthermore, improper handling can lead to inefficient results and increased operational costs.

Understanding the nuances of these systems is key. Users often overlook minor adjustments that can enhance efficiency. Regular maintenance and operator training are essential. Ultimately, mastering the use of agitated film evaporators can lead to substantial improvements in production processes.

Understanding the Basics of Agitated Film Evaporators and Their Applications

Agitated film evaporators are crucial in various industries, especially in food and pharmaceuticals. They utilize thin film technology for efficient evaporation and concentration processes. Reports indicate that these systems can enhance evaporation rates by up to 50%. This efficiency is significant for companies aiming to reduce energy costs and increase production capacity.

Understanding the basics of agitated film evaporators is vital. These devices operate by spreading liquid across a heated surface. As the liquid moves, it forms a thin film. This design promotes rapid heat transfer, leading to quick evaporation. However, maintaining the right temperature is critical. Too high a temperature can degrade sensitive materials, while too low can slow the process.

Applications of agitated film evaporators are diverse. Industries often use them for concentrating fruit juices or pharmaceuticals. Yet, operators must reflect on their processes. Over time, fouling can occur on the surfaces, which reduces efficiency. Regular maintenance is essential but often overlooked. Balancing operational efficiency with equipment upkeep is a challenge many face.

Key Operational Parameters for Maximizing Efficiency in Film Evaporation

Understanding key operational parameters is crucial for maximizing the efficiency of agitated film evaporators.

Temperature control plays a significant role in these systems. Maintaining the right temperature

ensures that the liquid has the optimal viscosity, allowing for better film formation. If the temperature is too high, it may cause undesired film buildup.

Yet, if it’s too low, the evaporation process slows down.

The pressure inside the evaporator also requires attention. Lowering pressure can enhance the evaporation rate by reducing the boiling point of the liquid.

However, excessively low pressure might lead to incomplete evaporation. Monitoring these adjustments is essential. Small fluctuations

can have large impacts.

Another vital aspect is the feed rate. Feeding the liquid too quickly can lead to flooding, disrupting

the film formation. Conversely, a slow feed rate might not utilize the evaporator’s capacity effectively. Operators need to find the sweet spot.

Continuous assessment and recalibrating based on real-time data is necessary to adapt to changing conditions. Each parameter interrelates, making it critical

to adjust them simultaneously for efficient operation.

Best Practices for Preventing Fouling in Agitated Film Evaporators

Agitated film evaporators play a crucial role in many industrial processes. However, fouling is a significant issue that can disrupt their efficiency. A recent industry report highlighted that fouling can reduce heat transfer rates by up to 50%. This directly impacts productivity. Therefore, managing fouling is essential for optimal operation.

One key best practice is maintaining proper temperature control. High temperatures can accelerate fouling, particularly with viscous liquids. It's vital to monitor temperature fluctuations closely. Another practice is regular cleaning schedules. Cleaning removes residues that contribute to fouling, extending the evaporator's lifespan. Ensure that cleaning agents are compatible with the materials involved.

Additionally, using proper pump design can prevent inefficient flow patterns. Turbulence in the liquid film enhances heat transfer but can also lead to fouling. Therefore, selecting the right pump ensures a steady flow and reduces the likelihood of buildup. Monitoring flow rates is also necessary. A slow flow rate may allow particles to settle, resulting in more fouling. Implementing these strategies can lead to more efficient operations and prolonged equipment life.

Top 5 Tips for Using Agitated Film Evaporators Effectively

| Tip | Description | Best Practice | Expected Outcome |

|---|---|---|---|

| Maintain Optimal Temperature | Ensure the temperature is consistent and optimal for the material. | Regularly monitor and adjust heating systems. | Reduced fouling and enhanced efficiency. |

| Control Feed Concentration | Adjust the concentration of the feed to the evaporator to match system specifications. | Perform regular feed composition analysis. | Prevent excessive buildup and achieve consistent results. |

| Implement Regular Cleaning Schedule | Maintain a consistent cleaning schedule to address fouling. | Use appropriate cleaning agents and techniques. | Maximize operational uptime and efficiency. |

| Monitor Flow Rates | Ensure flow rates are maintained within design specifications. | Install flow meters and perform routine checks. | Enhanced heat transfer performance. |

| Choose Proper Material of Construction | Select materials that are resistant to fouling. | Consult with materials experts for selection. | Decreased maintenance costs and extended equipment life. |

Monitoring and Controlling Temperature and Pressure for Optimal Performance

Monitoring and controlling temperature and pressure are crucial for optimal performance in agitated film evaporators. Maintaining the right temperature ensures efficient evaporation rates. If the temperature is too high, product degradation can occur. Too low, and you risk incomplete evaporation. Regularly check your gauges. Consistency is key.

Pressure management is equally important. A drop in pressure can lead to decreased boiling points, affecting the process. Adjusting the pressure settings may be necessary to maintain efficiency. It’s not just about initial setup; ongoing adjustments are often required. Mistakes happen. Equipment may not react as expected, and recalibrating might be needed.

Pay attention to the details. A minor fluctuation could mean significant changes in output quality. Invest time in training operators to recognize these variations. It creates a culture of awareness and responsiveness. Inconsistent temperature or pressure can lead to unwanted results, requiring constant vigilance and sometimes a new approach. Reflection on these aspects can help improve overall operations.

Evaluating Energy Consumption and Recovery Techniques in Film Evaporation Systems

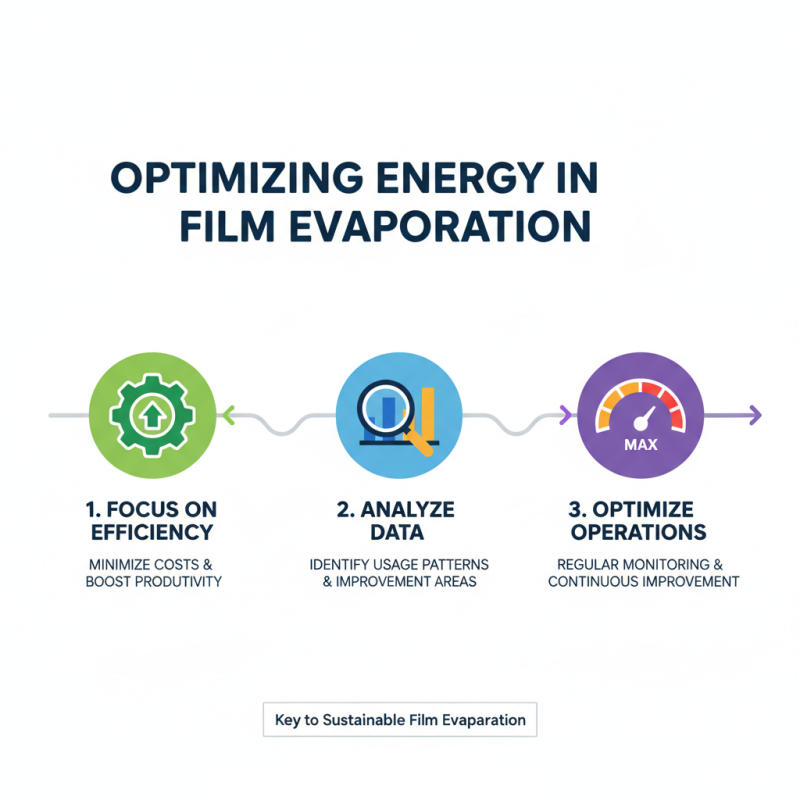

When assessing energy consumption in film evaporation systems, it's essential to focus on efficiency. This approach minimizes costs and enhances productivity. Regularly analyze energy usage data. It can reveal patterns that may suggest areas for improvement. Keeping a close eye on these metrics is crucial for optimizing operations.

Here’s a tip: ensure your systems are well-maintained. Neglected equipment can lead to higher energy usage. Maintenance should include checking for leaks and optimizing flow rates. These small actions can have big savings over time.

Recovery techniques are another critical consideration. Using heat exchangers to reclaim energy from vapor can significantly reduce consumption. However, it requires a thoughtful design. Not all systems are compatible, and careful planning is essential. Pilot tests may help in understanding specific needs.

In any case, always revisit your strategies. Technology evolves quickly, and remaining stagnant can lead to inefficiencies. The path to improvement often involves trial and error. Reflecting on past operations can highlight mistakes worth addressing.

Related Posts

-

Top 10 Benefits of Luwa Thin Film Evaporator for Industrial Applications?

-

Top 10 Benefits of Thin Film Evaporators for Efficient Distillation Processes

-

What is a Thin Layer Evaporator and How Does It Work

-

Top 10 Tips for Using a White Film Evaporator Effectively

-

Why Choose a Luwa Thin Film Evaporator for Your Industrial Process Needs

-

What is a White Film Evaporator and How Does It Work?