Employment Application Apply

Top 5 Tips for Using LCI Wiped Film Evaporators Effectively

The LCI wiped film evaporator has become an indispensable tool in the chemical and pharmaceutical industries, noted for its efficiency in handling viscous materials and temperature-sensitive compounds. Recent industry reports indicate that the market for evaporators, including wiped film technology, is expected to witness a substantial compound annual growth rate (CAGR) of approximately 6.5% from 2023 to 2030. This growth is driven by the increasing demand for advanced separation technologies that enhance product purity and yield.

One of the primary advantages of the LCI wiped film evaporator is its capability to operate under reduced pressure, significantly minimizing thermal degradation of sensitive components while achieving high evaporation rates. This technology is particularly effective in applications involving high-boiling solvents and heavy viscous liquids, making it a preferred choice for industries producing fine chemicals, food products, and pharmaceuticals. However, to capitalize on the efficiencies and advantages offered by these systems, operators must adopt best practices that maximize performance and longevity.

In this article, we will explore the top five tips for utilizing LCI wiped film evaporators effectively. By implementing these strategies, manufacturers can optimize their processes, reduce operational costs, and ensure consistent product quality, all crucial in maintaining a competitive edge in a rapidly evolving market landscape.

Understanding the Basics of LCI Wiped Film Evaporators

Wiped film evaporators are essential in various industrial processes, particularly in the concentration and purification of heat-sensitive materials. These devices operate by continually wiping a thin film of liquid across a heated surface, allowing for efficient evaporation of solvents or volatile components. Understanding the mechanics of wiped film evaporators is crucial for optimizing their use. The design typically includes a vertical orientation, which aids in quick and effective vapor removal, minimizing thermal degradation of the materials being processed.

Central to their function is the wiping mechanism, which ensures that the liquid is spread evenly on the heated surface, increasing the surface area for evaporation. This mechanism also prevents the liquid from pooling, which could lead to uneven heating and inefficiencies. Users must pay careful attention to parameters such as temperature, feed rate, and vacuum pressure, as these factors will significantly influence the performance of the evaporator. Mastery of these fundamentals empowers operators to maximize yields and enhance the overall efficiency of their processes.

Top 5 Tips for Using LCI Wiped Film Evaporators Effectively

| Tip | Description | Benefits |

|---|---|---|

| Optimize Temperature | Ensure the evaporator operates at the optimal temperature for specific materials. | Improves separation efficiency and product quality. |

| Maintain Correct Feed Rate | Adjust the feed rate to match the evaporator's capacity for better performance. | Prevents overloading and enhances throughput. |

| Regular Maintenance | Schedule regular checks to maintain components and cleanliness. | Extends equipment lifespan and ensures consistent operation. |

| Use Proper Wiping Mechanism | Select an appropriate wiping tool to maximize film thickness control. | Enhances heat transfer efficiency and product yield. |

| Monitor Operating Conditions | Continuously track pressure and temperature for adjustments. | Ensures stable operation and optimal product recovery. |

Maximizing Efficiency: Key Operating Parameters to Consider

When operating wiped film evaporators, understanding and optimizing key operating parameters is crucial for achieving maximum efficiency in the separation of components. One of the most significant parameters is temperature. Studies indicate that maintaining the evaporator wall temperature within an optimal range can significantly enhance the evaporation rate and product quality. For instance, operating at a temperature that is approximately 10-15°C above the boiling point of the component being separated can reduce residence time and minimize thermal degradation, leading to a higher yield of desirable product.

Another critical factor is the feed rate. Research from process engineering reports demonstrates that varying the feed rate directly alters the residence time within the evaporator, impacting both efficiency and product purity. A lower feed rate usually allows for better separation, as the components have more time to evaporate. However, it is essential to find a balance, as excessively low feed rates may result in reduced throughput. It is advisable to conduct trials to determine the ideal feed rate for specific applications, ensuring that the process operates within the most productive parameters.

Additionally, vacuum pressure plays a pivotal role in the efficiency of wiped film evaporators. Operating under optimal vacuum conditions can lower the boiling point of components, resulting in increased evaporation rates and improved energy efficiency. Industry data indicates that a vacuum level of around 0.1 to 1 mbar is generally effective for most applications, which not only enhances performance but also reduces energy consumption, thus leading to a more sustainable operation overall. By carefully adjusting these parameters, operators can maximize the efficiency of wiped film evaporators and optimize their separation processes.

Choosing the Right Material for Optimal Performance

Choosing the right material for wiped film evaporators (WFEs) is crucial for achieving optimal performance and efficiency. According to a report by the International Journal of Chemical Engineering, selecting the appropriate material can enhance thermal conductivity by up to 30%, significantly impacting the evaporation rate and overall effectiveness of the system. Materials with high thermal conductivity, such as stainless steel and certain alloys, are commonly preferred for their durability and resistance to corrosion, ensuring consistent performance over time.

In addition to thermal properties, chemical compatibility plays a vital role in material selection. The process of evaporation can introduce highly reactive substances, and utilizing materials that withstand corrosive environments is essential. Research from the American Institute of Chemical Engineers highlights that improper selection can lead to material degradation, costing businesses an estimated 5-10% in operational downtime and maintenance. Therefore, an analysis of the physical and chemical requirements of the materials involved in the specific evaporation process is necessary to ensure that the wiped film evaporator operates efficiently and safely.

Top 5 Tips for Using LCI Wiped Film Evaporators Effectively

Understanding the optimal materials for different applications can significantly enhance the performance of wiped film evaporators. The following chart illustrates the performance metrics of various materials based on thermal conductivity, viscosity, and overall efficiency in wiped film evaporators.

Maintenance Best Practices for Long-lasting Equipment

To ensure the longevity and efficient operation of wiped film evaporators, it is crucial to adhere to a set of best maintenance practices. Regular inspections are essential, as they allow operators to identify and address potential issues before they escalate. Checking seals and gaskets for wear and tear can prevent leaks and maintain optimal vacuum levels. Additionally, monitoring the cleanliness of the evaporator surfaces is vital, as residue buildup can detrimentally affect performance and product purity.

Another key aspect of maintenance is the lubrication of moving parts. Timely and appropriate lubrication reduces friction, thereby minimizing wear and tear and ensuring smooth operation. Operators should also be mindful of the coolant levels and temperatures during operations, as these factors play a significant role in the efficiency of the evaporation process. Finally, keeping a detailed maintenance log enables teams to track performance trends and schedules, making it easier to plan for necessary repairs and replacements, ultimately leading to a more cost-effective operation.

Common Challenges and Solutions in Wiped Film Evaporation

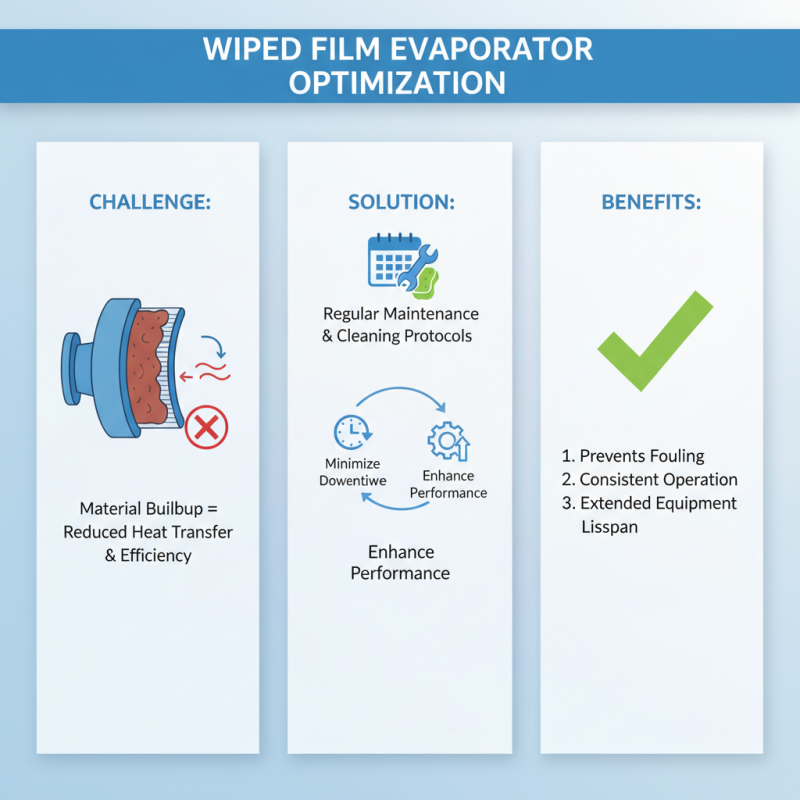

Wiped film evaporators are essential tools in various industries, yet they often present specific challenges during operation. One common issue is the buildup of material on the evaporator's surface, which can hinder optimal heat transfer and decrease efficiency. To combat this, regular maintenance and cleaning protocols should be established to prevent material fouling. Implementing an effective cleaning schedule not only minimizes downtime but also enhances the overall performance of the evaporator.

Another challenge faced in wiped film evaporation is the control of viscosity in the feed material. High-viscosity feeds can lead to ineffective film formation, resulting in subpar evaporation rates. To address this issue, it is critical to optimize the feed temperature and flow rate. By adjusting these parameters, operators can ensure a balanced viscosity that promotes a uniform film on the evaporator surface, leading to improved mass transfer and separation efficiency. Ultimately, understanding and tackling these common challenges can significantly enhance the effectiveness of wiped film evaporation processes.

Related Posts

-

What is a VTA Thin Film Evaporator and How Does It Work

-

What is a Thin Layer Evaporator and How Does It Work

-

Top 10 Benefits and Applications of Pope Wiped Film Evaporator Technology

-

2025 Top Film Evaporator Technologies and Trends You Need to Know

-

Top 10 Benefits of Thin Film Evaporators for Efficient Distillation Processes

-

Top 10 Benefits of Using Luwa Evaporator for Your Industrial Processes