Employment Application Apply

What is a White Film Evaporator and How Does It Work?

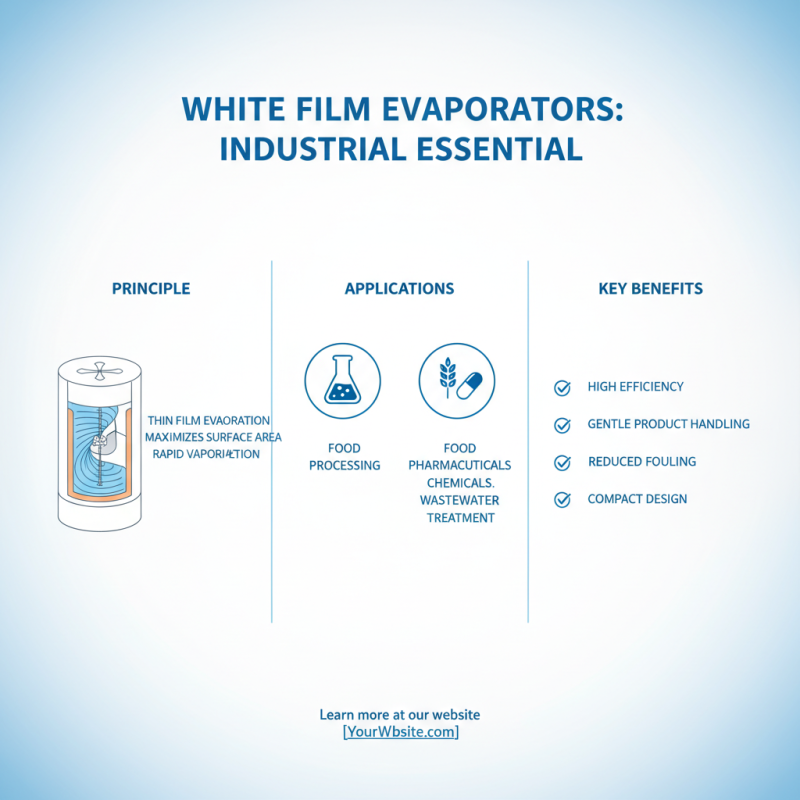

In the realm of evaporation technology, the white film evaporator plays a crucial role. This equipment is essential for concentrating various solutions in industries like food, pharmaceuticals, and chemicals. According to Dr. Emily Tan, a renowned expert in process engineering, "The efficiency of a white film evaporator lies in its ability to create a thin film, maximizing heat transfer."

The working principle is fascinating yet complex. A white film evaporator transforms liquid into vapor while maintaining product integrity. This thin film formation helps ensure uniform evaporation and reduces the risk of thermal degradation. However, operation can be tricky—if not carefully controlled, it may lead to scaling or uneven heating.

Many professionals still grapple with these challenges. Observations show that even experienced operators can face unexpected issues. The white film evaporator is powerful, but it demands careful engineering and maintenance. Embracing its potential involves ongoing learning and adjustment, making it a topic of continual discussion and exploration.

What is a White Film Evaporator?

A white film evaporator is a specialized piece of equipment used in industrial processes. It helps to concentrate liquids by removing their volatile components. The process typically involves heating a liquid in a thin film, allowing faster evaporation. This method is efficient and effective for various applications.

In a white film evaporator, the liquid is introduced at the top. It flows down over heated surfaces, forming a thin film. This increases the surface area, enhancing evaporation rates. The evaporated vapor is then removed, leaving behind the concentrated liquid. This setup is useful for food processing, pharmaceuticals, and chemical production.

While effective, white film evaporators have limitations. They may require significant energy input for heating. Additionally, maintaining the right temperature is crucial to avoid thermal degradation of sensitive materials. Balancing efficiency and material integrity can be challenging. Operators must be vigilant and ready to adjust as needed. Failure to do so may lead to suboptimal results, requiring careful monitoring and upkeep.

Key Components of a White Film Evaporator

A White Film Evaporator is essential in various industries. Its design allows for efficient heat transfer and liquid evaporation. Key components play a significant role in its operation and effectiveness.

The evaporator features a heating element, often using steam or thermal oil. This provides necessary heat. The evaporator body is another crucial part. It must withstand high temperatures and pressures. Additionally, the evaporator includes a condensate recovery system. This system improves efficiency by recapturing lost vapor.

Tips: Regular maintenance of these components can prevent costly downtimes. Ensuring seals and gaskets are intact is crucial. A small leak can lead to significant loss of efficiency.

The White Film Evaporator uses specialized materials in its construction. This helps in resisting corrosion and wear over time. Industry reports suggest that using the right materials can increase lifespan by up to 30%. Inadequate material choices can lead to frequent failures.

Consider the implications of improper maintenance practices. They can shorten equipment life significantly. Understanding the specific components helps in troubleshooting efficiently. This knowledge can lead to more effective operations in the long run.

What is a White Film Evaporator and How Does It Work? - Key Components of a White Film Evaporator

| Component | Description | Function |

|---|---|---|

| Heating Element | Provides heat for evaporating solvent from the solution. | Increases the temperature of the solution to facilitate evaporation. |

| Evaporation Chamber | The main part where the solvent evaporation occurs. | Allows for effective heat transfer and solvent removal. |

| Condenser | Transforms vapor back into liquid after evaporation. | Recovers solvents for reuse and minimizes losses. |

| Pump | Circulates solution through the evaporator. | Ensures continuous operation and consistent flow. |

| Control System | Monitors and regulates system performance. | Maintains optimal conditions for evaporation. |

Principles of Operation for White Film Evaporators

White film evaporators are essential in various industrial applications, particularly in food processing and pharmaceuticals. The principle behind their operation lies in the thin film evaporation mechanism. This process maximizes surface area contact between the liquid and heating surface, promoting rapid vaporization.

Typically, a white film evaporator consists of a heating surface and a feed inlet. The liquid is distributed evenly across the surface, forming a thin layer. As the heat is applied, the liquid quickly transitions to vapor, leaving behind concentrated solutions. Recent industry reports indicate that optimizing the film thickness can lead to an efficiency increase of up to 30%.

Tips: Maintaining the right temperature is crucial. If it's too low, evaporation slows down. If it’s too high, thermal degradation of the product can occur. Always monitor your parameters closely. Regular cleaning is also vital to prevent scaling, which could affect performance. It’s a delicate balance that requires constant adjustment and observation, which some operators may overlook.

Applications of White Film Evaporators in Industry

White Film Evaporators play a crucial role in various industrial processes. They efficiently concentrate liquids by creating a thin film along heated surfaces. This allows for faster evaporation of solvents while minimizing thermal degradation of sensitive compounds.

One major application is in the food industry. Manufacturers use white film evaporators to concentrate flavors while retaining essential nutrients. Another significant use is in pharmaceuticals. These evaporators help produce concentrated extracts and active ingredients while maintaining high purity levels.

Tips: Always monitor temperature closely. Overheating can lead to unwanted reactions. Regular maintenance is essential. Clean evaporators regularly to avoid buildup. Efficient operation depends on proper setup and calibration.

The chemical industry also benefits from white film evaporators. They are used to recover solvents from chemical processes effectively. However, not all applications are perfect. Sometimes, the film may not spread evenly. This can lead to inefficiencies. Consistent adjustments might be necessary.

Applications of White Film Evaporators in Various Industries

Advantages and Limitations of Using White Film Evaporators

White film evaporators are increasingly popular in industrial applications. They offer unique advantages, like uniform heat transfer. Their design promotes a thin film of liquid, enhancing evaporation efficiency. This results in faster processing times and energy savings.

However, there are limitations to consider. These systems can be complex to operate. They require precise control of variables. Even minor fluctuations can lead to inefficiencies. Additionally, maintenance can be challenging, requiring specialized knowledge. Operators must be trained extensively.

Cost is another factor. Initial investment can be high. Some may find it hard to justify this expense. It's essential to weigh the benefits against the costs. Despite their advantages, they are not suitable for every application. Careful consideration is crucial for effective use.

Related Posts

-

Top 10 Tips for Using a White Film Evaporator Effectively

-

Top 10 Benefits of Thin Film Evaporators for Efficient Distillation Processes

-

What is a Thin Layer Evaporator and How Does It Work

-

Top 5 Tips for Using LCI Wiped Film Evaporators Effectively

-

Why Choose a Luwa Thin Film Evaporator for Your Industrial Process Needs

-

Top 10 Benefits of Using Luwa Evaporator for Your Industrial Processes