Employment Application Apply

Wiped Film Evaporator Tips for Efficient Operation and Maintenance?

Wiped film evaporators are essential in various industries for efficient thermal processing. They offer effective ways to concentrate and purify materials. According to Dr. Jane Smith, a leading expert in thermal separation processes, "Proper maintenance of wiped film evaporators can greatly enhance operational efficiency."

Many users overlook critical maintenance practices. Regular inspections, for example, are often neglected. A lack of attention can lead to increased downtime. Ensuring the right temperatures and flow rates is vital for optimal performance.

Understanding the nuances of wiped film evaporators can be challenging. Operators may struggle with settings that are too high or too low. These mistakes can hinder efficiency. It's crucial to develop a routine that addresses these common oversights. Regular training can enhance knowledge about this vital equipment.

Understanding the Basics of Wiped Film Evaporators

Wiped film evaporators are essential for the efficient concentration and purification of materials. They operate by using a thin film of liquid on the evaporator’s surface. This design maximizes the surface area for heat transfer. As the liquid is wiped into a thin layer, it evaporates efficiently. The process allows for continuous operation, making it suitable for high-viscosity products.

Understanding the basics is crucial for proper maintenance. Regular cleaning of the evaporator's surface can prevent build-up. Inspecting the wiper blades should be part of the routine. Sometimes, wear and tear can go unnoticed. Inadequate maintenance may lead to decreased efficiency and product loss.

Operators should be aware of temperature control. Incorrect settings can affect product quality. Monitoring feed rates is another critical factor. Too fast can overwhelm the system; too slow can lead to clogging. All these elements require careful attention to detail. Balancing these factors can ensure effective operation of wiped film evaporators.

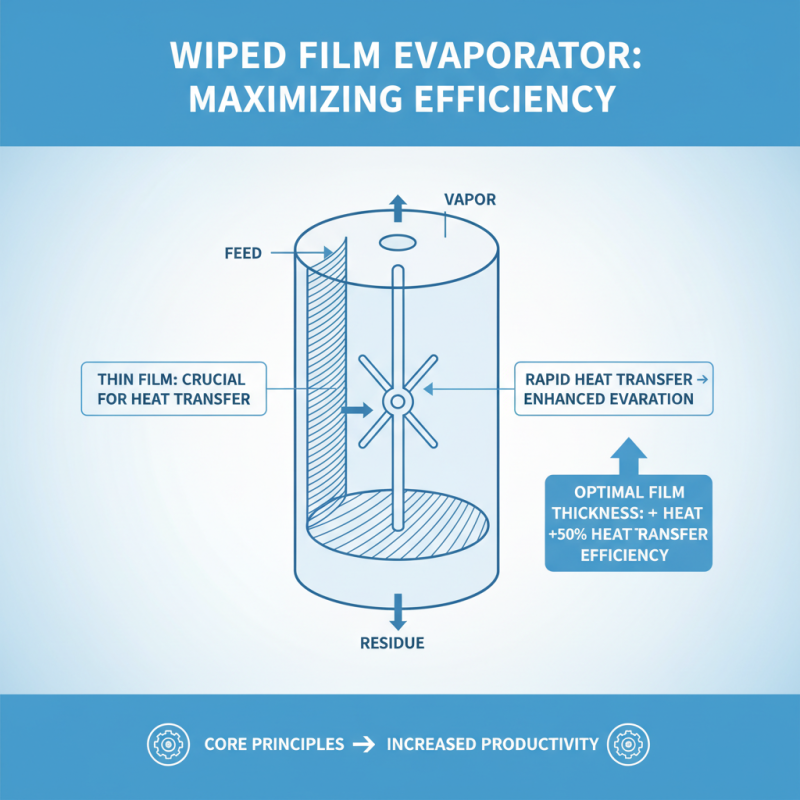

Key Operational Principles for Maximizing Efficiency

Maximizing efficiency with a wiped film evaporator requires understanding its core principles. The thin film formed during operation is crucial. This design allows for rapid heat transfer, enhancing evaporation rates. Reports indicate that optimal film thickness can improve heat transfer by up to 50%.

Maintaining operational consistency is key. Operators should regularly check feed rates and temperatures. Inefficient settings can lead to fouling or over-evaporation. Studies show that regular cleaning can boost performance by 20% or more. Small details, like ensuring proper sealing, can prevent leaks that waste valuable materials.

Monitoring energy consumption is essential for efficiency. Using real-time data analytics can identify areas for improvement. However, many facilities overlook energy assessments. In fact, integrating energy-efficient practices can reduce operational costs significantly. Awareness and regular training can create a culture focused on efficiency.

Routine Maintenance Procedures for Wiped Film Evaporators

The effective operation of wiped film evaporators relies heavily on routine maintenance. Regular checks can prevent unexpected downtime and costly repairs. Start by inspecting all seals and gaskets. Look for signs of wear and replace them when necessary. These parts are critical for maintaining pressure and preventing leaks.

Cleaning is vital as well. Residue buildup can affect performance. Schedule cleaning sessions based on your usage frequency. Typically, every few weeks is advisable. Use appropriate solvents and ensure all components are thoroughly dried before reassembling. Consider setting reminders for these tasks.

It’s essential to monitor performance metrics. Keep a close eye on temperature and pressure readings. If you notice anomalies, investigate them promptly. Reflection on maintenance strategies can lead to improvements. Over time, habits may fall into disrepair, hindering efficiency. Always be open to adjusting your maintenance protocols based on observations.

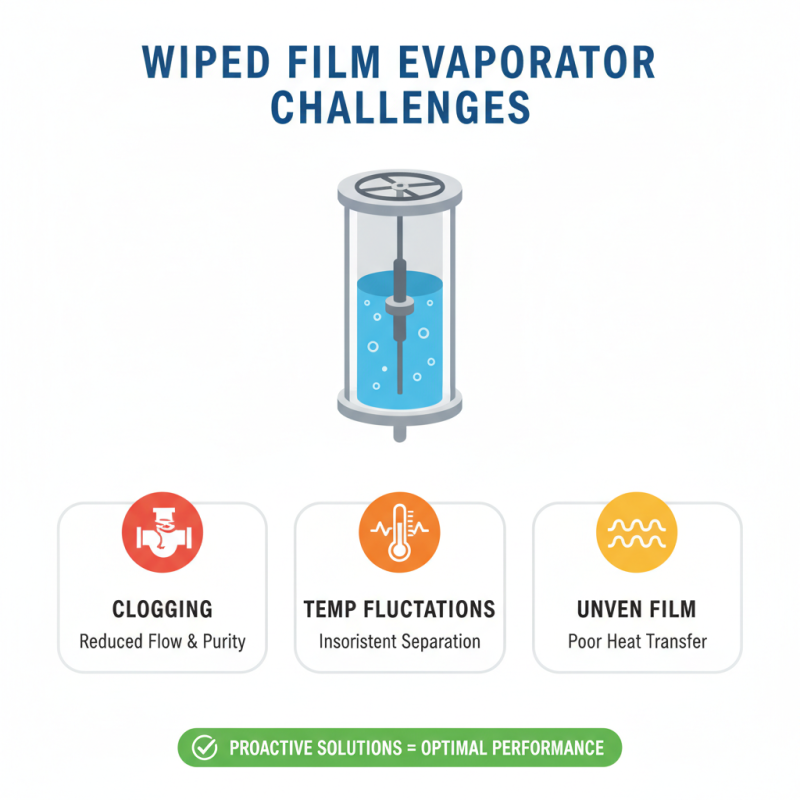

Common Challenges and Troubleshooting Tips

Wiped film evaporators are crucial for effective separation and purification processes. However, operators often face several challenges that affect efficiency. Issues like clogging, temperature fluctuations, and uneven film thickness can hinder performance. It’s vital to address these challenges proactively.

Regular maintenance is key. Check seals for wear and tear. Replace them if necessary. This ensures optimal performance and reduces leaks. Pay attention to flow rates. Low flow can lead to uneven film formation. Adjust your settings to maintain a consistent flow. This will help in achieving a uniform film thickness.

Another common problem is frothing. This can increase product loss and reduce efficiency. To tackle frothing, control your feed rate. Slow it down if needed. Monitor the temperature closely. If it fluctuates, it may lead to additional issues. Having routine checks can save time and resources. Ultimately, facing these challenges takes practice and reflection. Each problem teaches valuable lessons for future operation.

Best Practices for Optimal Performance and Longevity

To achieve optimal performance with a wiped film evaporator, regular maintenance is crucial. Keeping the equipment clean can significantly impact its efficiency. Dust, residues, and deposits can reduce heat transfer. Inspect parts regularly. Pay attention to seals and gaskets; these are often overlooked but essential for preventing leaks.

Another tip is monitoring operating temperatures. High temperatures can lead to product degradation. Use calibrated gauges to ensure accuracy. If temperatures spike, it may indicate a problem. Adjust settings carefully. Document any changes to identify patterns over time.

Finally, training staff on proper operation is vital. Each operator should understand the equipment's functions and potential issues. They should also be aware of safety protocols. Regular workshops can enhance skills. Emphasizing the importance of communication during troubleshooting can prevent unnecessary downtime. Remember that sometimes, a simple adjustment can make a significant difference.

Wiped Film Evaporator Performance Metrics

Related Posts

-

What is a Thin Layer Evaporator and How Does It Work

-

Top 10 Tips for Using a White Film Evaporator Effectively

-

How to Optimize Your WFE Evaporator for Maximum Efficiency and Performance

-

Top 5 Tips for Using Agitated Film Evaporators Effectively?

-

Top Benefits of Using Pfaudler Wiped Film Evaporator in Industrial Applications?

-

Top 10 Benefits of Using Luwa Evaporator for Your Industrial Processes